Sublimation metal products let you put colorful images on metal. You use the sublimation process to do this. The metal must have a polyester coating. This coating helps keep the colors bright. People like these products because they look great and last long. They are useful for many things. More people are learning about dye sublimation. The demand is growing quickly because it is easy and flexible.

Metric/Segment | Value/Forecast |

|---|---|

Global sublimation printing market (2021) | |

Projected market size (2030) | USD 1,803.60 million |

Metal and stainless steel applications | Growing sector |

Key Takeaways

Sublimation metal products use heat and pressure to put bright images into metal with a polyester coating. These products have bright colors and are very strong. They have smooth surfaces and are good for gifts, signs, home decorations, and awards. You need a heat press, special sublimation inks, transfer paper, and polyester-coated metal to do sublimation printing. Sublimation prints do not fade, peel, or scratch easily. This makes them great for use inside or outside. Sublimation needs special materials and tools, but it makes special, high-quality items that look different and last a long time.

Sublimation Metal Products

What They Are

When you think of sublimation metal products, you might see shiny metal with bright pictures. These items start as plain metal sheets or objects. Manufacturers put a polyester or polymer coating on them. This coating is very important. Without it, the ink will not stick. Your design would not last long.

Dye sublimation is a special way to print. It uses heat and pressure to turn solid dye into gas. The gas goes into the polyester coating on the metal. When the metal cools, the dye turns solid again. This locks your image inside the coating. The print will not crack, peel, or fade easily. A heat press works best for this process. It gives the right heat and pressure every time.

You can find sublimation metal products in many places. People use them for awards, signs, home décor, and gifts. Common items are plaques, photo panels, keychains, and promo products. Some, like DuraLuxe, are made for outdoor use. They resist UV rays, scratches, and graffiti. Others, like Dynasub, are better for indoors. They may fade in sunlight.

Did you know? Dye sublimation printing is not just for metal. It also works on polyester fabrics and other polymer-coated surfaces. This makes it great for custom T-shirts, mugs, and more.

Key Features

Sublimation metal products have many good features. Here are some you will notice:

Vivid Colors: Dye sublimation printing makes images look bright and sharp. The colors pop because the ink bonds with the coating.

Durability: Your designs last a long time. The images do not fade, scratch, or peel. Some even last outdoors for years.

Smooth Finish: The surface feels smooth. You cannot feel the image on top. It becomes part of the product.

Versatility: You can print almost any design. It works for small keyrings or big signs.

Eco-Friendly: Dye sublimation uses less water and fewer chemicals. The process is cleaner and better for the planet.

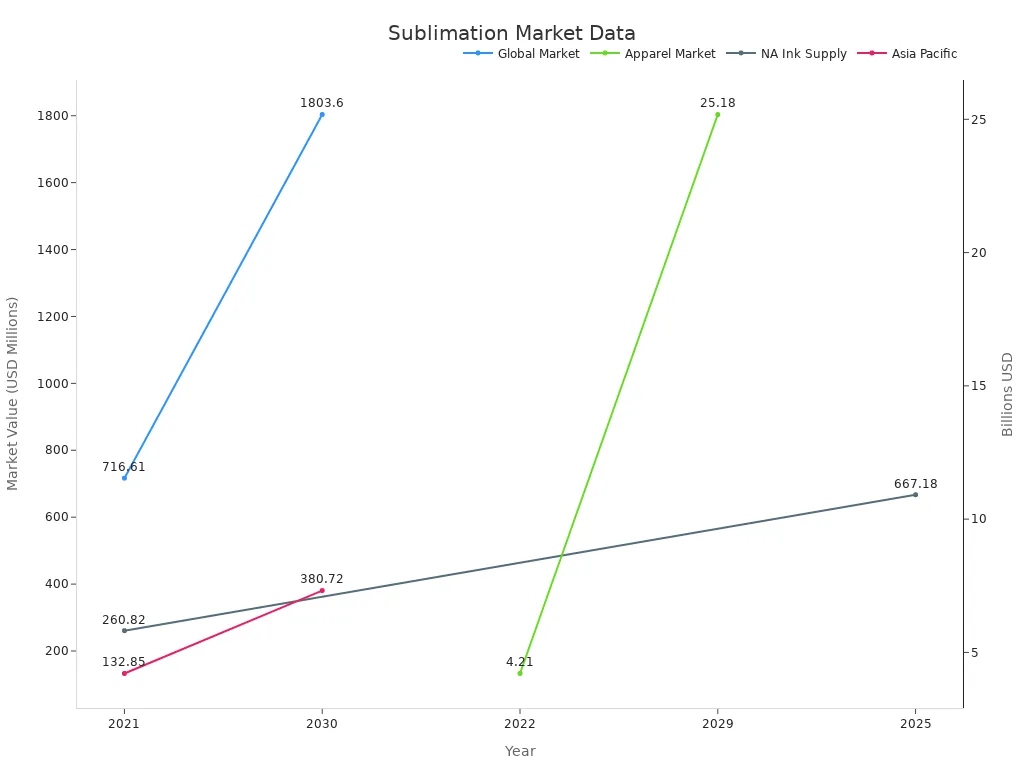

The market for sublimation metal products is growing fast. Here are some facts:

The global sublimation paper market may reach over $1.2 billion by 2035.

Fast-drying sublimation paper is popular for high-quality results.

Dye sublimation printing is worth $16 billion. More people want custom, eco-friendly products.

The Asia Pacific region leads because of strong manufacturing.

You need a heat press, sublimation transfer paper, and special inks to start. The heat press is very important. It helps the dye turn into gas and bond with the metal. This technology lets you make high-resolution, full-color prints that last.

Tip: Always check if your metal product has a polyester or polymer coating before you try dye sublimation. Regular metal will not work.

Sublimation metal products help you make lasting, eye-catching items. You can create a unique gift or a professional sign. This technology helps your work stand out.

Sublimation Process

How It Works

You might wonder how dye sublimation turns a blank metal sheet into a colorful sign or photo panel. The sublimation process uses heat and pressure to make this magic happen. First, you print your design onto special sublimation paper using sublimation inks. Next, you place the printed paper face-down on the metal. The metal must have a polyester coating for the dye sublimation to work.

Now comes the most important step. You use a heat press to apply high heat and pressure. The heat press usually reaches temperatures between 350°F and 400°F. When you press the paper and metal together, the sublimation inks turn into gas. This gas moves right into the polyester coating on the metal. As the metal cools, the gas turns back into a solid. Your image becomes part of the metal, not just sitting on top.

Tip: The heat press gives you bright, full-color graphics that last for years. You can even use dye sublimation for detailed photos and artwork.

The sublimation process works best when you control the temperature and pressure. Scientists use tools like thermogravimetric analysis to measure how fast the inks turn to gas. They also check how well the heat press transfers energy. This helps you get sharp, even prints every time.

Required Materials

You do not need a lot of fancy tools to start with dye sublimation printing. Here is what you need:

A sublimation printer (like Epson or Sawgrass)

Sublimation inks made for your printer

Sublimation transfer paper

A heat press (flat, mug, or cap press, depending on your project)

Blank metal products with a polyester coating

You can find many types of metal for sublimation printing. Aluminum is popular for ornaments, keychains, and name tags. Steel works well for message boards. Some companies use fiberglass-reinforced plastic or MDF for plaques and frames. The finish can be gloss white, clear, or gold. Thicknesses range from 0.020″ to 0.045″ for most metal sheets.

Material | Common Uses | Finishes | Thicknesses |

|---|---|---|---|

Aluminum | Ornaments, tags | Gloss white, gold, clear | 0.020″-0.045″ |

Steel | Message boards | Gloss white | 0.023″ |

MDF | Frames, plaques | Gloss white, gold | 0.045″ |

Note: Only use metal with a polyester coating. Regular metal will not work with the sublimation process.

You also need to use the right sublimation inks and transfer paper. These help your design move from the paper to the metal during dye sublimation. The heat press is the key tool that brings everything together. With these materials, you can start making your own custom sublimation products at home or in a small shop.

Types of Sublimation Metal Products

Common Items

Dye sublimation is used on many metal items today. It adds bright colors and cool designs to metal products. If you look around, you will see some popular things made with dye sublimation printing:

Metal ornaments: These have pictures on both sides. The images stay nice for a long time.

Keychains and name tags: You can add photos, logos, or words to these.

Photo panels and sublimation plaque products: These turn your best photos into art that lasts.

Metal signage: Businesses use these signs because the graphics look sharp and bright.

Bottles and thermoses: Many companies make custom drinkware with dye sublimation.

Medals and promotional items: Sports teams and companies give these out as awards or gifts.

Every metal surface needs a polyester coating before you start. This coating helps the ink stick during the heat press step. Without it, your design will not stay or last.

Here is a quick chart showing some common metals and what they are used for:

Metal Substrate | Common Items Made by Sublimation | Finishes Available | Thickness |

|---|---|---|---|

Aluminum | Ornaments, Keychains, Name Tags | Gloss White, Gloss Clear, Gloss Gold, Semi-Gloss White | 0.5mm, 0.76mm, 1.14mm |

Steel | Message Boards | Gloss White | 0.58mm |

Dye sublimation printing on metal gives you bright, strong images. You get a smooth surface and clear details each time.

Specialty Products

Dye sublimation can make even more special items. These show how flexible this process is. In technology, companies use dye sublimation to control tiny amounts of metals like sodium, potassium, magnesium, iron, and copper. These metals can change shape and size during sublimation. For example, copper particles can be between 200 and 400 nanometers. This shows how many ways sublimation metal products can be used, even in high-tech places.

You might also see custom metal art, outdoor photo panels, or machine parts made with dye sublimation. Some companies make special collectibles or branded items. The heat press lets you put detailed designs on almost any coated metal.

Tip: Always check if your blank metal item has a polyester coating before you start. This step is very important for dye sublimation printing to work.

Dye sublimation lets you make many creative things. You can create everyday items or special products that are unique.

Uses of Sublimation Products

Sublimation products have changed the way you can decorate, advertise, and give gifts. You see them everywhere, from busy stores to cozy homes. These products stand out because they show bright colors, last a long time, and let you use your own designs. Let’s look at some of the most popular ways you can use sublimation metal products.

Signage and Displays

You want your sign to get noticed. Sublimation makes that easy. You can print full-color graphics on metal signs, which means your message pops with bright colors and sharp details. Businesses use these signs for menus, store hours, and special sales. You might see them in schools, hospitals, or even at sports fields.

Sublimation products work well for displays at trade shows or events. You can show off your brand or artwork with metal panels that do not fade or scratch easily. These displays stay looking new, even after lots of use. If you want to change your display often, sublimation lets you update your graphics without much trouble.

Tip: Sublimation signs are great for outdoor use. They resist sunlight, rain, and even graffiti, so you do not have to worry about them wearing out fast.

Awards and Gifts

You can make someone feel special with a custom award or gift. Sublimation metal products help you do that. You can add names, dates, or photos to medals, plaques, and trophies. These awards look professional and last for years.

The market for sublimation awards and gifts keeps growing. New heat press machines make it easier to print detailed designs on metal. Companies use these machines to create high-quality awards and promotional items. This helps more people choose sublimation products for special events, sports, or business gifts.

You can also make unique gifts for birthdays, holidays, or graduations. A photo on a metal panel or a custom keychain shows you care. These gifts do not fade or peel, so your memory stays bright.

Custom medals for sports teams

Personalized plaques for students or workers

Photo keychains for friends and family

Home Decor

You can bring art into your home with sublimation products. Metal photo panels turn your favorite pictures into wall art. You can hang them in your living room, bedroom, or office. The colors stay vivid, and the surface feels smooth.

Many people use sublimation to make custom clocks, coasters, or even light switch covers. You can match your home’s style or create something totally new. These products do not need much care. Just wipe them clean, and they look as good as new.

Note: Sublimation home decor is perfect for photographers and artists. You can sell your work as metal prints that last for years.

Sublimation products give you lots of choices. You can use them for advertising, decorating your home, or giving a special gift. They stand out because they are strong, colorful, and easy to customize.

Benefits and Limitations of Sublimation

Advantages

Sublimation on metal has many good points. The colors look bright and clear. The ink goes into the coating, so images do not peel or fade. You can make gifts, signs, or art that last for years. Sublimation works for detailed photos and designs. It is good for outdoor signs because prints resist sun and rain.

Here is a simple chart to compare sublimation on different metals:

Metric | GaSb Metal Substrate (CSS) | GaAs Substrate (CSS) |

|---|---|---|

Lattice Mismatch | −5.7% (smaller mismatch) | −13.9% (larger mismatch) |

Interfacial Mismatch Dislocations | Fewer dislocations | More dislocations |

Leakage Current | Lower leakage current | Higher leakage current |

Resistivity | Higher resistivity | Lower resistivity |

Energy Resolution (241 keV γ ray) | 17% (better resolution) | 31% (poorer resolution) |

Growth Rate | Fast | Fast |

Cost | Low | Low |

This table shows that some metal substrates give better results. They work well for special uses.

You also get these benefits:

Images are inside the metal, not just on top.

Prints stay bright and clear for a long time.

You can make many things, from keychains to big signs.

Tip: Sublimation is great if you want your designs to last and look nice.

Drawbacks

Sublimation has some downsides too. You need special tools like a heat press and a printer for sublimation inks. These tools cost more than normal printers. You must use metal with a polyester coating. Regular metal will not work, so you have fewer choices.

Here are some things to remember:

Sublimation only works on polyester or poly-coated surfaces.

You need good materials for the best results.

Not all metals or products will work.

Note: If you want to print on wood, glass, or plain metal, sublimation will not work unless those items have a special coating.

Sublimation gives great results, but you need to plan for costs and use the right materials.

You now know that sublimation metal products let you create lasting, colorful items for home, business, or gifts. You get bright images that do not fade or peel. Studies show that sublimation methods help keep materials strong and stable, so your projects last longer. If you want to start, try small items like sublimation plaque products. Always check for a polyester coating before you print. This way, you get the best results every time.

FAQ

What makes sublimation metal products different from regular printed items?

You get images that become part of the metal, not just stuck on top. The colors stay bright and do not peel or fade. These products last longer than regular prints.

Can I use any metal for sublimation printing?

No, you need metal with a polyester coating. Regular metal will not work. Always check the label before you start your project.

How do I clean sublimation metal products?

You can wipe them with a soft, damp cloth. Avoid harsh cleaners or scrubbing pads. Your images will stay clear and bright with simple care.

What are sublimation plaque products used for?

You can use sublimation plaque products for awards, signs, or special gifts. They show off photos, names, or messages in a way that lasts and looks professional.