Quando você compara Filme DTF vs. Filme de Sublimação 3D, você pode ver que eles são distintos em suas aplicações. O filme DTF pode imprimir em uma variedade de tecidos e superfícies, enquanto o filme de sublimação 3D é mais eficaz em poliéster e itens revestidos. O filme DTF produz cores vivas e possui acabamento texturizado, enquanto a sublimação oferece impressões suaves que lembram fotografias. Ambos os tipos são duráveis e têm uma longa vida útil. O filme DTF é ideal para trabalhos pequenos ou personalizados, enquanto a sublimação é mais adequada para pedidos grandes e proporciona custos mais baixos por item.

O mercado de impressão DTF poderá atingir US$ 1,7 bilhão até 2026.

A impressão por sublimação de tinta já está em alta US$ 14,9 bilhões e está crescendo rapidamente.

Atributo | Filme DTF | Filme de sublimação 3D |

|---|---|---|

Compatibilidade de materiais | Funciona em muitos tecidos e superfícies | Melhor para poliéster leve e itens revestidos |

Qualidade de impressão | Cores brilhantes e aparência texturizada | Acabamento liso que parece uma foto |

Durabilidade | Resiste ao desbotamento, arranhões e rasgos | As cores permanecem no interior para resultados duradouros |

Custo | Bom para trabalhos pequenos ou médios | Melhor para grandes pedidos e baixo custo por item |

Volume de produção | Rápido para pequenos lotes e trabalhos sob demanda | Funciona bem para pedidos grandes, mas leva mais tempo |

Compreender essas diferenças entre o filme DTF e o filme de sublimação 3D ajuda você a escolher o melhor método para o seu projeto.

Takeaways -chave

O filme DTF funciona em muitos tecidos como algodão e poliéster. Isso o torna bom para trabalhos personalizados.

O filme de sublimação 3D é melhor para superfícies duras e revestidas. Cria impressões que parecem fotos e duram mais.

Escolha o filme DTF para pequenos lotes e designs personalizados. Use a sublimação para grandes pedidos e impressão em massa.

O filme DTF oferece cores brilhantes e detalhes nítidos. A sublimação proporciona imagens suaves e nítidas.

Pense nas necessidades do seu projeto e nos materiais que você usa. Isso ajuda você a escolher entre filme DTF e filme de sublimação 3D.

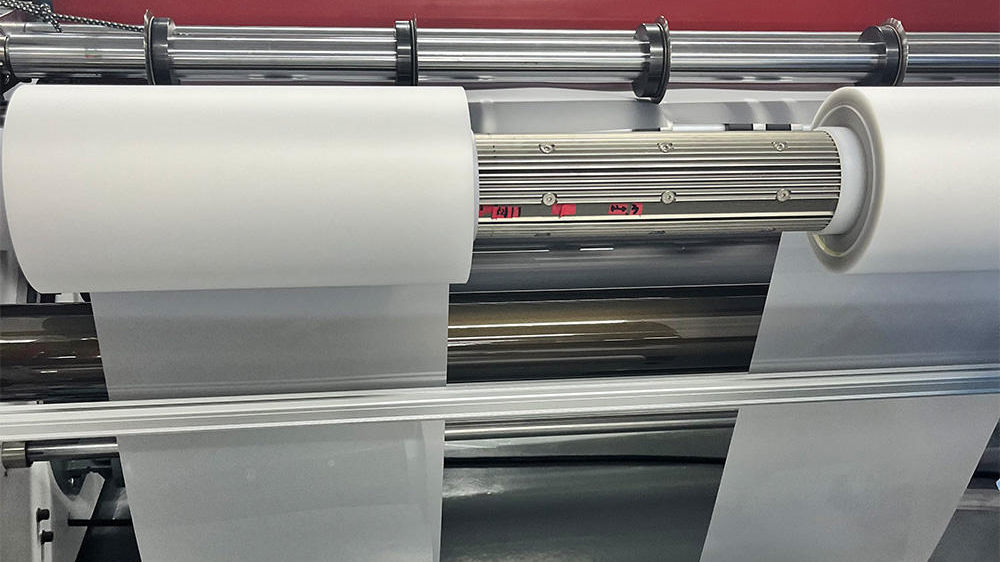

Visão geral do filme DTF

Como funciona

A impressão em filme DTF usa um processo passo a passo que permite criar designs coloridos em vários tecidos. Aqui está como você pode usar este método:

Imprima seu desenho em um filme PET usando uma impressora DTF.

Aplique uma camada de pó hot melt no filme impresso.

Cure o pó aquecendo-o, o que o torna pegajoso.

Use uma prensa térmica para transferir o desenho do filme para a sua roupa.

Retire o filme após pressionar e verifique a impressão final.

Esse processo ajuda você a obter impressões nítidas e vibrantes sem a necessidade de pré-tratar o tecido. Você pode usar o filme DTF para projetos pequenos e grandes.

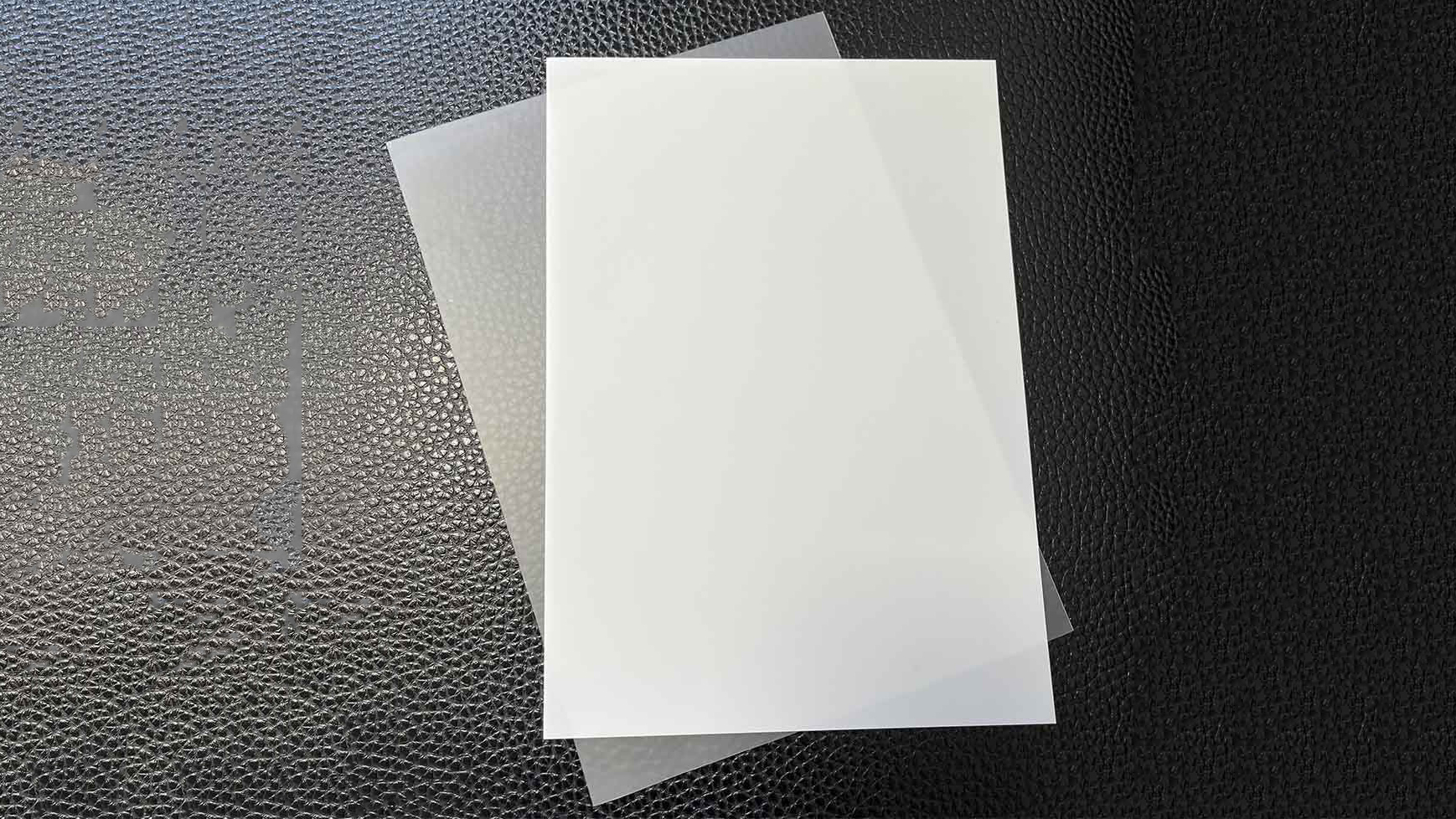

Características

O DTF Film se destaca por suas características únicas. Você pode escolher entre diferentes tipos de casca, como casca fria, morna, quente ou instantânea. Cada tipo proporciona uma experiência de peeling diferente. A camada de liberação pode ser à base de óleo ou água, o que afeta a durabilidade e o preço acessível de suas impressões. Você também pode escolher entre acabamentos foscos e brilhantes, para que seus designs fiquem do jeito que você deseja. O filme DTF vem em diversas espessuras, como 50um, 75um e 100um. Filmes mais espessos podem fazer com que suas impressões durem mais e pareçam mais profissionais.

Tipo de recurso | Descrição |

|---|---|

Opções de peeling frio, quente, quente e instantâneo | |

Camada de liberação | À base de óleo ou à base de água |

Efeito de superfície | Acabamento fosco ou brilhante |

Espessura do Filme Base | 50um, 75um, 100um |

Dica: Escolher a combinação certa de recursos pode ajudar você a obter os melhores resultados para seu projeto.

Materiais Compatíveis

Você pode usar o filme DTF em uma ampla variedade de materiais. Isso o torna mais versátil do que muitos outros métodos de impressão. Aqui está uma tabela mostrando quais materiais funcionam melhor:

Material | Detalhes de compatibilidade |

|---|---|

Forte adesão e impressões vibrantes | |

Poliéster | Impressões brilhantes e boa adesão |

Nylon | Funciona, mas manuseie com cuidado devido ao calor |

Seda | Compatível para impressão |

Couro | Pode ser usado de forma eficaz |

Jeans | Bons resultados, sem necessidade de pré-tratamento |

Fibra Química | Compatível para impressão |

Ao comparar o filme DTF com o filme de sublimação 3D, você notará que o filme DTF funciona em mais tipos de tecidos. Essa flexibilidade ajuda você a realizar muitos trabalhos de impressão diferentes.

Visão geral do filme de sublimação 3D

Como funciona

O filme de sublimação 3D ajuda a colocar imagens em itens curvos. Primeiro, você imprime seu desenho em um filme especial de sublimação com uma impressora. Então, você enrola o filme em volta do objeto. Você coloca o item embrulhado em uma prensa térmica a vácuo 3D. A máquina usa calor e pressão para transformar o corante em gás. O gás entra na superfície do seu item. Isso faz com que a imagem fique para sempre. Esse método é ótimo para canecas, capas de telefone e itens com curvas ou bordas. O design não descasca nem desbota porque a tinta passa a fazer parte do item.

Características

O filme de sublimação 3D é conhecido por ser forte e confiável. Fornece imagens brilhantes e claras. O filme pode se mover e dobrar durante o processo sem perder qualidade. Ele também resiste às intempéries e à luz solar, para que suas impressões durem mais. Você pode usar este filme em itens com formas complicadas e o design não ficará bagunçado. Este processo também gera menos desperdício, por isso economiza dinheiro em comparação com os métodos antigos.

Recurso | Descrição |

|---|---|

Fidelidade de cores superior | Alcança mais de 98% de transferência de cores com resultados vibrantes e de alta definição. |

Maior durabilidade e resistência | Mantém a integridade durante o alongamento; resiste às intempéries e à exposição aos raios UV. |

Versatilidade para formas complexas | Transfere projetos para superfícies curvas ou 3D sem distorção. |

Eficiência de produção e relação custo-benefício | Minimiza a perda de material em comparação com os métodos de impressão tradicionais. |

Dica: Se você deseja que seus designs pareçam fotos reais e durem muito tempo, o filme de sublimação 3D é uma escolha inteligente.

Materiais Compatíveis

Você pode usar filme de sublimação 3D com muitos materiais resistentes ao calor. Esses materiais devem suportar altas temperaturas, até 230°C (446°F), durante o processo. Aqui estão algumas escolhas comuns:

As membranas de silicone resistentes ao calor funcionam bem com máquinas de sublimação 3D como a ST-3042 e a ST-1520.

Muitos itens revestidos, como canecas, capas de telefone e placas de metal, aceitam corantes de sublimação.

Cada pacote de membranas de silicone geralmente contém 10 folhas, então você tem o suficiente para muitos projetos.

Ao comparar o filme DTF com o filme de sublimação 3D, você verá que o filme de sublimação 3D funciona melhor para superfícies duras e revestidas e itens com formas complicadas. Isso o torna uma ótima opção para presentes personalizados e produtos especiais.

Filme DTF vs. Filme de Sublimação 3D

Compatibilidade de materiais

O Filme DTF e o Filme de Sublimação 3D funcionam em materiais diferentes. O filme DTF imprime em algodão, poliéster, náilon, seda, couro, jeans e fibras químicas. Você não precisa tratar o tecido primeiro. Isso torna o filme DTF ideal para trabalhos personalizados. O filme de sublimação 3D funciona melhor em poliéster leve e itens revestidos. Essas superfícies devem suportar altas temperaturas. Se quiser imprimir em canecas, capas de telefone ou placas de metal, use a sublimação. Para camisetas, moletons e tecidos mistos, o DTF Film oferece mais opções.

Dica: Use filme DTF para vários tipos de tecidos. Escolha filme de sublimação 3D para superfícies duras e revestidas.

Qualidade de impressão

Você deseja que suas impressões tenham uma aparência brilhante e nítida. O filme DTF e o filme de sublimação 3D proporcionam cores fortes. O filme DTF destaca as cores e mostra detalhes nítidos. Você vê linhas finas e bordas nítidas. A impressão por sublimação cria designs suaves. As cores se misturam como uma foto. Aqui está uma tabela para ajudá-lo a comparar:

Método de impressão | Vibração de cores | Resolução |

|---|---|---|

Impressão DTF | Maior vibração e nitidez | Detalhes mais nítidos e linhas mais finas |

Impressão de sublimação | Designs vívidos e de tons contínuos | Excelente vibração de cores |

Se você deseja cores fortes e linhas nítidas, escolha Filme DTF. Se você deseja impressões suaves e parecidas com fotos, a sublimação é uma boa escolha.

Durabilidade

Você quer impressões que durem após a lavagem e o uso diário. O Filme DTF e o Filme de Sublimação 3D têm durabilidade diferente. O filme DTF resiste ao desbotamento, arranhões e rasgos. As estampas ficam lisas e esticam bem. Eles não racham e duram muito tempo. As impressões por sublimação são duráveis, mas não funcionam em todos os tecidos. O filme DTF atende aos padrões ASTM de resistência à lavagem e à abrasão. Estudos mostram que o filme DTF dura mais do que a serigrafia em muitos tecidos. Aqui está uma tabela para mostrar os resultados:

Tipo de filme | Resistência à lavagem | Resistência à abrasão | Notas |

|---|---|---|---|

Filme DTF | Alto | Alto | Suave, elástico e duradouro |

Filme de sublimação 3D | Moderado | Moderado | Boa durabilidade, menos versátil |

Padrões ASTM | Atendido/Excedido | Atendido/Excedido | As transferências DTF atendem a todos os padrões |

Estudo NIST | Mais durável | Menos durável | DTF supera a impressão em tela |

Se você deseja impressões que permaneçam brilhantes e durem mais, o filme DTF é uma boa escolha.

Custo

Você quer economizar dinheiro ao imprimir. O Filme DTF e o Filme de Sublimação 3D têm custos diferentes. O equipamento DTF Film custa mais no início, mas os suprimentos são mais baratos. Você usa menos tinta branca e não precisa de líquidos especiais. O equipamento de sublimação custa menos para iniciantes, mas você precisa de itens revestidos e mais tinta branca. Aqui está uma tabela para comparar custos:

Categoria | Custos do filme DTF | Custos de filmes de sublimação 3D |

|---|---|---|

Equipamento básico | US$ 2.500 – US$ 3.000 | <US$ 1.000 |

Equipamentos Industriais | $ 15.000 + | Até US$ 25.000 para DTG de gama média |

Custo de consumíveis | Mais barato que as tintas DTG | Mais de US$ 3.500 para configuração completa |

Uso de tinta branca | Menos tinta branca necessária | É necessária mais tinta branca |

Transferir filmes | Opções baratas de alta qualidade | Líquidos e equipamentos de pré-tratamento necessários |

A impressão DTF geralmente custa menos que a impressão por sublimação.

As transferências DTF funcionam em muitos tecidos sem tratamento especial, portanto você economiza dinheiro.

As folhas DTF custam menos que o papel de sublimação e o pó adesivo é mais barato.

Se você tem uma pequena empresa ou deseja imprimir em vários tecidos, o Filme DTF ajuda você a gastar menos.

Volume de produção

Pense em quantos itens você deseja imprimir. O filme DTF e o filme de sublimação 3D funcionam melhor para diferentes necessidades. O filme DTF é rápido para pequenos lotes e trabalhos personalizados. Você pode imprimir designs rapidamente. A sublimação funciona bem para grandes pedidos. Você paga menos por item ao imprimir muitas peças. Se você deseja imprimir centenas de canecas ou capas de telefone, a sublimação é eficiente. Para camisetas personalizadas ou pequenas tiragens, o filme DTF é melhor.

Nota: O filme DTF é flexível para pequenos trabalhos. O filme de sublimação 3D é melhor para imprimir muitos itens.

Prós e Contras

Prós e contras do filme DTF

Quando você olha para o filme DTF, você vê muitos pontos fortes que o tornam popular para impressão personalizada. Você pode imprimir em algodão, poliéster, couro e muito mais. Essa versatilidade ajuda você a lidar com muitos tipos de projetos. O filme DTF oferece impressões brilhantes e detalhadas que ficam ótimas, mesmo em designs pequenos. Você não precisa gastar muito na configuração, por isso funciona bem para pequenas empresas ou pedidos personalizados. O processo é fácil de aprender, então você pode começar a imprimir rapidamente.

Vantagem | O que isso significa para você |

|---|---|

Impressões de alta qualidade | Seus designs parecem vívidos e nítidos, mesmo com detalhes finos. |

Versatilidade | Você pode imprimir em vários materiais, não apenas em um tipo de tecido. |

Durabilidade | As impressões duram muitas lavagens e uso regular. |

Preparação gráfica rápida | Você pode preparar projetos rapidamente, o que ajuda com prazos apertados. |

Baixos custos de produção | Você economiza dinheiro, especialmente em tiragens pequenas ou personalizadas. |

Fácil de aprender | Você não precisa de muito treinamento para começar. |

Sem custos de configuração | Você evita taxas de configuração caras para cada novo design. |

Mais opções de produção | Você pode imprimir lotes grandes e pequenos sem pré-tratamento. |

Dica: A DTF Film ajuda você a expandir seus negócios, oferecendo mais opções e economizando dinheiro em pequenos trabalhos.

No entanto, você também deve estar ciente das desvantagens. O custo inicial de uma impressora DTF pode ser alto. Você precisa manter a manutenção regular ou poderá observar uma qualidade de impressão inferior ou jatos entupidos. Alguns os usuários se preocupam com o impacto ambiental porque nem todos os filmes e tintas são fáceis de reciclar. As impressões DTF podem não durar tanto quanto as impressões por sublimação, especialmente depois de muitas lavagens. Projetos grandes podem parecer menos respiráveis, o que pode causar desconforto se usados por muito tempo.

Alto investimento inicial em equipamentos.

É necessária manutenção frequente para obter melhores resultados.

Preocupações ambientais com o descarte de filmes e tintas.

As impressões podem rachar ou desbotar após muitas lavagens.

Não é ideal para designs grandes e de cobertura total devido à respirabilidade.

Prós e contras do filme de sublimação 3D

O Filme de Sublimação 3D também traz benefícios exclusivos para seus projetos de impressão. Você pode criar imagens semelhantes a fotos com acabamentos suaves. Esse método funciona melhor em superfícies duras e revestidas, como canecas, capas de telefone e placas de metal. As estampas passam a fazer parte da peça, por isso não descascam nem desbotam facilmente. Você pode usar esse processo para itens com curvas ou arestas, o que é difícil para outros métodos. A sublimação é eficiente para pedidos grandes, então você paga menos por item ao imprimir em grandes quantidades.

Produz imagens suaves e de alta resolução que parecem fotos reais.

Funciona bem em objetos curvos ou 3D.

As impressões duram muito tempo e resistem ao desbotamento ou descascamento.

Ótimo para produção de alto volume e pedidos em grandes quantidades.

Não há necessidade de pré-tratamento em itens revestidos.

Mas você enfrenta alguns limites com o filme de sublimação 3D. Você só pode usá-lo em poliéster ou superfícies com revestimento especial. Você não pode imprimir em algodão ou em muitos tecidos naturais. O processo precisa de alta temperatura, portanto nem todos os itens são seguros para uso. O equipamento pode não ser adequado para trabalhos pequenos e personalizados porque funciona melhor para lotes grandes. Você também precisa comprar blanks revestidos, o que pode aumentar seus custos.

Nota: Ao comparar o filme DTF com o filme de sublimação 3D, pense nas necessidades do seu projeto. O filme DTF oferece mais opções de materiais, enquanto o filme de sublimação 3D oferece qualidade de imagem incomparável em superfícies duras.

Aplicativos

Casos de uso de filme DTF

O filme DTF é bom para muitos trabalhos de impressão personalizados. Pequenas empresas, escolas e artistas utilizam-no muito. Você obtém cores vivas e estampas fortes em muitos tecidos. Aqui estão algumas maneiras pelas quais as pessoas usam o filme DTF:

Roupas personalizadas, como camisetas e moletons permitem que você faça designs especiais para cada pessoa.

Itens promocionais, como sacolas e chapéus, ajudam as marcas a serem notadas em eventos.

Roupas esportivas e uniformes de times permitem adicionar nomes, números e logotipos para cada jogador.

As decorações de interiores, como almofadas e arte nas paredes, tornam as casas mais pessoais.

Lojas virtuais para escolas e organizações sem fins lucrativos ofereça impressão para arrecadação de fundos o tempo todo.

Influenciadores e bandas vendem mercadorias em pequenas quantidades, sem grandes pedidos.

Marcas de streetwear e varejo usam filme DTF para gráficos ousados e cores brilhantes.

O filme DTF mantém os desenhos nítidos, mesmo em tecidos grossos. Você pode imprimir designs ecológicos em bolsas e mochilas.

Casos de uso de filmes de sublimação 3D

O filme de sublimação 3D funciona bem para itens com curvas ou superfícies duras. É melhor para produtos revestidos e poliéster leve. Aqui está uma tabela com usos comuns:

Tipo de aplicativo | Exemplos |

|---|---|

Objetos Irregulares | Capas para celulares, geladeiras, aparelhos de ar condicionado |

Pequenos Eletrodomésticos | Produtos eletrônicos, tampas de vasos sanitários, teclados |

Itens Decorativos | Brinquedos, capacetes, cerâmica |

Você também pode imprimir em xícaras, copos, garrafas, mouse pads, vidros e cristais. Muitas indústrias usam filme de sublimação 3D, como automotivo, aeroespacial, eletrônico e dispositivos médicos.

Escolhendo o método certo

Ao comparar o filme DTF e o filme de sublimação 3D, pense nas necessidades do seu projeto. O filme DTF funciona em algodão, poliéster, misturas e couro. Você obtém cores vivas e estampas fortes em tecidos claros e escuros. O filme de sublimação 3D proporciona imagens suaves e fotográficas em superfícies revestidas e poliéster leve. Se você deseja imprimir em vários tipos de tecido, escolha o filme DTF. Se você precisa de impressões de alta qualidade em itens duros ou curvos, escolha Filme de Sublimação 3D. Além disso, pense em quantos itens você deseja imprimir. O filme DTF é ótimo para pequenos lotes e trabalhos personalizados. O filme de sublimação 3D é melhor para grandes pedidos e impressão em massa.

Dica: Escolha o método de impressão com base no material e no design. Isso ajuda você a obter os melhores resultados para cada projeto.

Quando você olha para o filme DTF e o filme de sublimação 3D, percebe que eles são diferentes. O filme DTF funciona em muitos tecidos e oferece cores brilhantes. Mas às vezes as impressões racham depois de muitas lavagens. O filme de sublimação cria imagens que parecem fotos em poliéster e coisas revestidas. Essas estampas durar mais e não descasque. A nova tecnologia utiliza tintas que são melhor para o meio ambiente e filmes que dobre facilmente. Se você quiser imprimir em muitos tecidos para pequenos trabalhos, use o filme DTF. Se você precisa de impressões fortes em superfícies duras e quer imprimir muito, opte pela sublimação.

Recurso | Filme DTF | Filme de sublimação 3D |

|---|---|---|

Materiais | Muitos tecidos | Poliéster, itens revestidos |

Durabilidade | Bom, pode quebrar | Excelente, sem descascar |

Qualidade de impressão | Vibrante, texturizado | Como uma foto, suave |

Escolha sempre o método de impressão que melhor se adapta ao seu projeto.

Perguntas frequentes

Qual é a principal diferença entre o filme DTF e o filme de sublimação 3D?

Você pode usar filme DTF em muitos tecidos, como algodão e poliéster. O filme de sublimação 3D funciona melhor em itens revestidos e de poliéster. O filme DTF oferece mais opções de materiais. O filme de sublimação cria impressões fotográficas em superfícies duras.

Posso usar filme DTF para canecas ou capas de telefone?

Você não deve usar filme DTF para canecas ou capas de telefone. O filme DTF funciona melhor em tecidos. Para canecas, capas de telefone ou outros itens rígidos, você precisa do filme de sublimação 3D.

Qual método dura mais após a lavagem?

As impressões por sublimação duram mais porque a tinta passa a fazer parte da peça. As impressões DTF permanecem brilhantes e fortes, mas podem rachar ou desbotar após muitas lavagens.

O filme DTF ou o filme de sublimação 3D são melhores para pequenas empresas?

Você pode começar com o filme DTF se quiser imprimir camisetas personalizadas ou pequenos lotes. O filme DTF custa menos para trabalhos pequenos. O filme de sublimação 3D funciona melhor se você imprimir muitos itens duros de uma só vez.