When you want vibrant and durable prints, you need to start with high-quality sublimation blanks. These blanks use the right material, like 100% polyester, which helps your colors pop and last through many washes. The smooth surface and tight weave of these high-quality sublimation blanks boost vibrancy and sharpness, making your custom printing projects stand out. Choosing the right coating and checking ink adhesion matter, too. You should always look for blanks that can handle the heat of your press and come from a supplier you trust. Picking high-quality sublimation blanks sets you up for strong, long-lasting results every time.

Key Takeaways

Pick sublimation blanks that are 100% polyester or have a strong polymer coating. This helps your prints look bright and last a long time.

Always test a sample blank with your heat press before you buy a lot. This makes sure the print looks good and the ink sticks well.

Buy from trusted suppliers who give you good products and fast help. They should also give you clear details about their blanks.

Make sure your blanks can take high heat without getting ruined. This helps your designs stay sharp and last longer.

Try to find a good balance between price and quality. Do not buy cheap blanks that can mess up your prints. Buy in bulk when it is smart to save money.

Criteria for High-Quality Sublimation Blanks

Material and Coating

You should check the material before picking sublimation blanks. Polyester is the best choice for sublimation printing. Try to use blanks made from 100% polyester or at least 65% polyester blends. More polyester means your prints will look brighter and last longer. If you pick blends with less than 65% polyester, your designs might look faded. Cotton and silk do not work well for sublimation printing, so you should not use them.

The coating on the blanks is also important. Good sublimation blanks have a special poly-coating added when they are made. This coating lets the sublimation dye turn into gas and stick to the surface when you use heat. If you use blanks with spray-on coatings or no coating, your results will not be good and you might waste money. Only blanks with the right poly-coating give you sharp, bright, and strong images.

Tip: Pick blanks that say “sublimation-ready” or “polymer-coated.” These are made for the best results with sublimation printing.

Here is a simple table to help you pick the right material:

Material Type | Sublimation Friendly? | Print Quality |

|---|---|---|

100% Polyester | ✅ | Bright & Durable |

65/35 Poly-Cotton | ✅ (with coating) | Good |

Cotton/Silk | ❌ | Poor |

Polymer-Coated Metal | ✅ | Excellent |

Heat Resistance

Sublimation printing uses high heat to move your design onto the blank. Not all materials can handle this heat. You need blanks that can take up to 400°F (204°C) without melting or losing their coating. If your blank cannot take the heat, your print will not look good and the blank could get ruined.

Polyester and polymer-coated items are made to handle this heat. They keep their shape and coating even after many presses. If you use materials that are not heat-resistant, you might ruin both your blank and your design.

Note: Always check the heat settings the maker suggests for your blanks. This helps you avoid using too much heat and damaging your items.

Ink Adhesion

Ink adhesion helps your design last a long time. When you use good blanks with the right coating, the sublimation ink turns into gas and goes deep into the surface. This makes prints that are bright, clear, and do not fade, peel, or crack.

If you use blanks with bad or uneven coatings, the ink will not stick well. You might see faded or patchy designs. Uneven heat or moisture can also cause problems with ink adhesion. To get the best results, always pre-press your blanks to remove moisture and use even heat and pressure.

Common reasons for poor ink adhesion:

Moisture in the blank or sublimation paper

Low polyester content or materials not made for sublimation

Bad sublimation paper or ink

Wrong temperature or pressure settings

Pro Tip: Test a sample blank before you start a big project. This helps you check the blanks and make sure your settings are correct.

When you pick high-quality sublimation blanks made from the right materials, with the right coating and heat resistance, you will do well. Your prints will look bright, last longer, and your customers will be happy.

Types of Sublimation Blanks

If you use the best sublimation blanks, your prints look brighter. They also last longer. Sublimation blanks come in many shapes and sizes. You can find them in different materials. Some popular choices are acrylic, aluminum, bamboo, ceramic, glass, hardboard, leather, polyester fabric, polymer, rubber, stainless steel, and wood. Let’s look at the main types. This will help you pick the right blank for your next project.

Best Sublimation Blanks for Apparel

Polyester is the best choice for apparel. T-shirts, hoodies, caps, and socks made from 100% polyester or at least 65% polyester blends work well. High polyester means your prints are bright and last a long time. If you use less polyester, your prints may look faded. Sublimation-ready t-shirts feel smooth and do not have coatings that block ink. Pre-pressing helps remove moisture. This gives you sharper prints.

Apparel Type | Best Sublimation Blanks | Why They Work Well |

|---|---|---|

T-Shirts | Bright, durable prints | |

Hoodies | Polyester fleece, microfiber | Hold color, feel soft |

Caps | Polyester fronts, trucker caps | Easy to print, bold colors |

Socks | Polyester blends, smooth finish | Full coverage, sharp designs |

Tip: Always check the label for polyester content before you buy blanks for apparel.

Drinkware and Home Décor

Drinkware and home décor make great gifts. They are also good for custom products. Mugs, tumblers, water bottles, and photo panels need a high-quality polymer or polyester coating. This coating lets the ink go deep into the surface. Your designs will be dishwasher-safe and will not fade or peel. For home décor, look for glossy finishes on coasters, photo tiles, and ornaments. Glossy finishes make your prints look extra bright.

Common drinkware and home décor blanks:

Ceramic mugs

Stainless steel tumblers

Glass photo panels

Sandstone coasters

Slate rock tiles

Note: The coating on mugs and tumblers is very important. A good coating keeps your design looking new, even after many washes.

Accessories and Other Blanks

You can get creative with accessory blanks. Keychains, phone cases, mouse pads, and puzzles are fun to print. Most of these have a polymer-coated surface. This helps your prints stay bright and not peel or crack. The best accessory blanks are strong and work well with your inks and printer. Always test a sample first. This helps you check color and sharpness.

Popular accessory blanks:

Keychains

Phone cases

Mouse pads

Ornaments

Awards plaques

Pro Tip: Sublimation printing bonds the ink into the blank. Your accessories can handle daily use and still look great.

When you pick the best sublimation blanks, your projects stand out. No matter what you print on, always check for the right material and coating. This helps your sublimation prints shine every time.

Choosing the Best Sublimation Blanks Supplier

Reputable Sources

You want to get your sublimation blanks from suppliers you can trust. Good suppliers help you avoid problems with your heat press and make sure your prints look great every time you press. Look for companies that have been around for years and work with big brands. Some trusted names in the industry include Unisub, Heat Transfer Warehouse, Pro World, INNOSUB USA, and Technotape. You can also check out Conde Systems, Joto, and Coastal Business Supplies. Buying directly from these manufacturers often gives you better prices and access to exclusive products.

When you pick a supplier, check for things like certifications (such as ISO 9001 or OEKO-TEX), ethical production, and clear supply chain information. Here’s a quick checklist to help you spot a reputable source:

Holds certifications like GOTS, OCS, or ISO 9001

Shares supply chain details and audit reports

Offers fast sample delivery

Responds quickly to questions (within 5 hours)

Works with well-known brands

Tip: Ask other people who do sublimation printing for supplier recommendations. Their experience can save you time and money.

Sample Testing

Before you buy a lot of blanks, always order samples. Testing samples with your heat press lets you check print quality, color, and durability. Press a few blanks and see how the colors look after you press and wash them. Make sure the coating holds up under heat and the ink does not fade or peel. This step helps you avoid wasting money on blanks that do not work well with your press.

Order a small batch of blanks.

Use your heat press to test them.

Check for color consistency and strong ink adhesion.

Wash or use the item to see if the print lasts.

Note: Good suppliers will send samples quickly and answer your questions about pressing settings.

Reviews and Support

Customer reviews and ratings can tell you a lot about a supplier. Look for feedback on platforms like Amazon, BBB, or Trustpilot. Reviews help you spot issues with heat press compatibility, shipping, or customer service. Some suppliers, like Heat Press Nation, offer lifetime support and troubleshooting. This kind of help makes it easier for you to solve problems with your press or get tips for better results.

Return policies matter, too. Check if the supplier has easy returns and clear rules. If you see lots of complaints about poor support or slow shipping, try another supplier. Good support means you can press with confidence and get help when you need it.

Cost and Value of Sublimation Blanks

Price vs. Quality

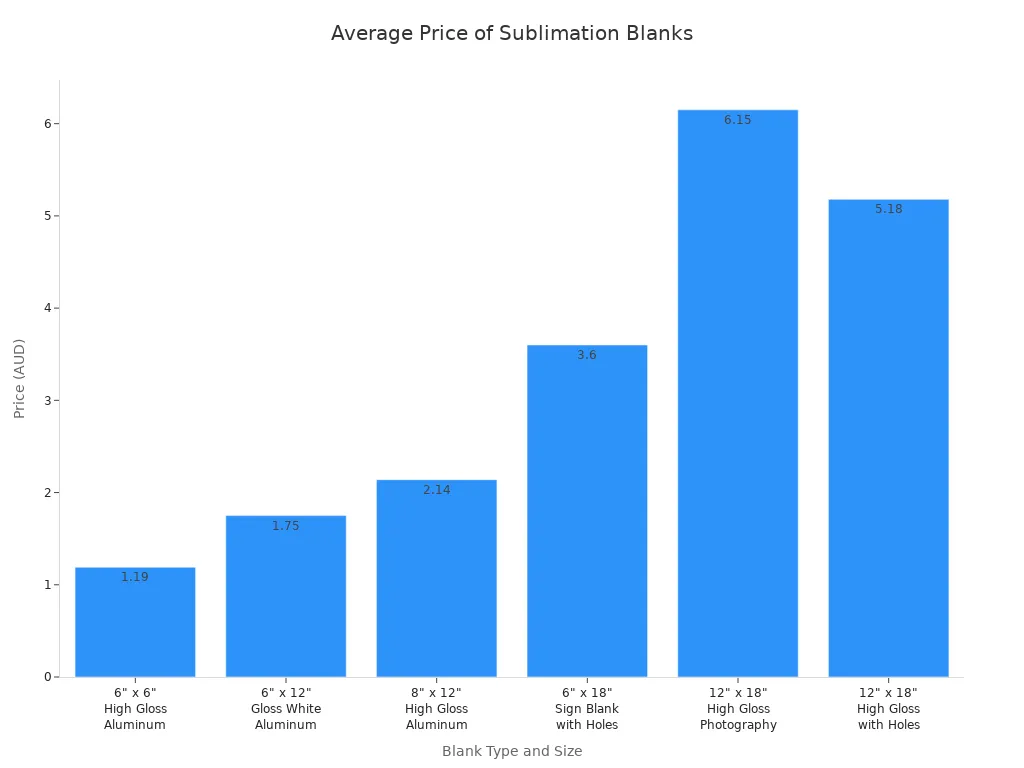

When you shop for sublimation blanks, you might notice a big range in prices. Some blanks cost just a dollar or two, while others can be much more expensive. For example, a 6″ x 6″ high gloss aluminum blank can cost about $1.19 AUD, and a larger 12″ x 18″ blank might cost over $6 AUD. Specialty items or bulk packs can go even higher. Take a look at this chart to see how prices can change based on size and type:

You might feel tempted to buy the cheapest blanks, but low prices often mean lower quality. Cheap blanks can have poor coatings or uneven surfaces. Your prints might fade, peel, or look dull. High-quality blanks cost more, but they give you bright, long-lasting results. You want your finished products to look great and last, so it makes sense to invest in better blanks.

Tip: Always check the material and coating before you buy. Saving a little money now can cost you more if your prints do not last.

Bulk Buying Tips

Buying in bulk can help you save money, especially if you print a lot. Here are some smart ways to get the best value:

Calculate all your costs. Add up the price of blanks, ink, paper, equipment, and your time. This helps you know the real cost for each item.

Compare prices from different suppliers. Look for discounts on larger orders or special deals.

Use tiered pricing. Some suppliers offer lower prices when you buy more. This can help you lower your cost per blank.

Negotiate with suppliers. Ask if they can give you a better price for a big order.

Watch out for shipping costs. Sometimes free shipping is only a good deal if the blanks are high quality.

Start with a smaller order to test quality. Once you trust a supplier, you can buy more and save.

Note: Always review your pricing and adjust if you see changes in the market or get feedback from customers.

When you balance price and quality, you get the most value from your sublimation blanks. Smart buying helps you make products that look great and keep your business strong.

When you want vibrant and durable prints, focus on these essentials:

Pick materials with high polyester content or strong polymer coatings.

Test samples before buying in bulk.

Work with suppliers who deliver consistent quality and support.

Check for coating flaws and match the blank to your project.

Great suppliers help you get the best vibrancy and long-lasting results. Start using these tips today and watch your custom prints stand out!

FAQ

What is the best material for sublimation blanks?

You get the best results with 100% polyester or polymer-coated items. These materials hold the ink well and make your prints look bright and sharp. Avoid cotton or silk because they do not work with sublimation.

How do I know if a blank is sublimation-ready?

Look for labels that say “sublimation-ready” or “polymer-coated.” You can also ask your supplier. If you feel a smooth, even surface, that is a good sign. Always test a sample first.

Can I use regular mugs or shirts for sublimation?

No, you need special blanks. Regular mugs and shirts do not have the right coating or polyester content. Your design will not stick or will wash off quickly. Always choose blanks made for sublimation.

Why do my prints look faded after pressing?

Low polyester content

Bad or uneven coating

Not enough heat or pressure

Moisture in the blank

Check these things before you press again. Testing a sample helps you find the problem.