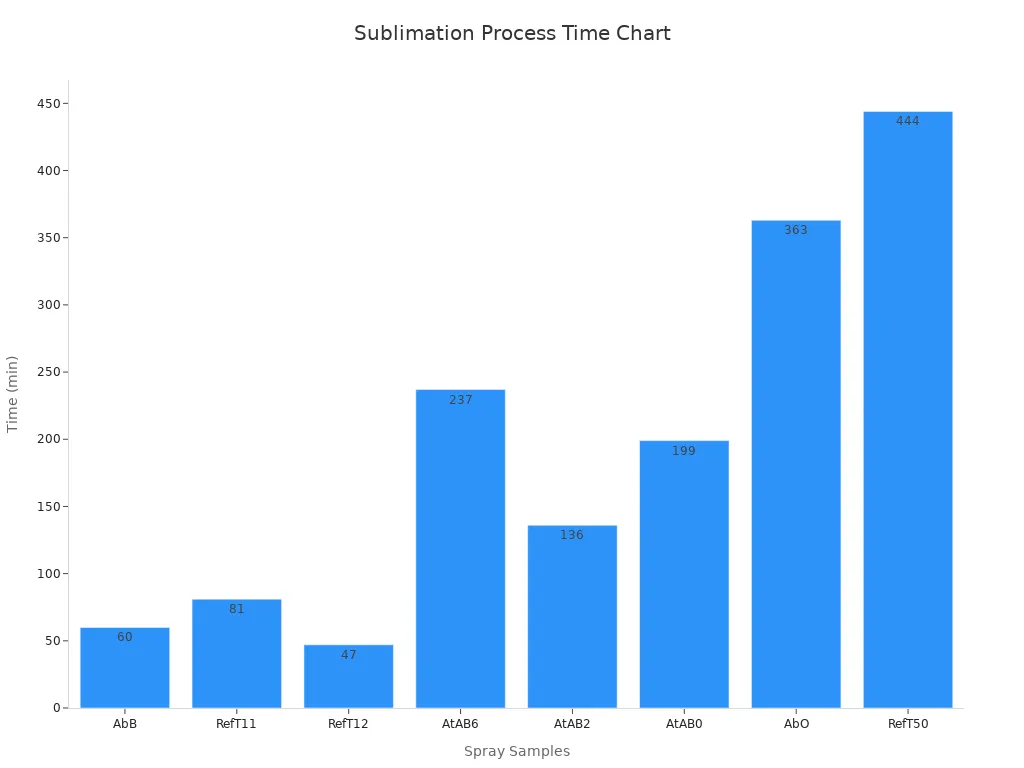

You use sublimation blanks to make custom designs with sublimation. These blanks have a special layer that helps the ink stick well. This makes your colors bright and helps them last longer. If you pick the wrong material, the ink will not stay. Your design might fade or look dull. The thickness and quality of the coating are important. For example, a six-layer coating can help scan quality, as you can see in the table below.

Spray Group | Sublimation Time (min, average ± SD) | Coating Thickness (µm) | Scan Quality (Sigma, µm) |

|---|---|---|---|

AbB | Tens of micrometers | Not specified | |

RefT11 | 81 ± 10 | Tens of micrometers | Not specified |

RefT12 | 47 ± 14 | Tens of micrometers | Not specified |

AtAB6 | 237 ± 48 | Not stated | ~9 |

AtAB2 | 136 ± 11 | Not stated | ~9 |

AtAB0 | 199 ± 54 | Not stated | ~9 |

AbO (six-layer) | 363 ± 54 | ~24 | 0.75 |

RefT50 | 444 ± 73 | ~24 | 0.75 |

When you pick good sublimation blanks, you get better and brighter results.

Key Takeaways

Pick sublimation blanks with at least 65% polyester. Choose light colors for bright and lasting designs. Use the right heat press settings. Set the correct temperature, time, and pressure. This helps you avoid faded or damaged prints. Always clean your blanks before starting. Secure your transfer paper with heat-resistant tape. This stops blurry or ghosted images. Choose blanks made for sublimation, like coated mugs, shirts, and phone cases. Do not use cotton or dark-colored items. Test your process on extra blanks first. This helps you get better and make sharp, colorful results every time.

En blanco de sublimación

What Are They

Sublimation blanks are made for sublimation. You use them to make custom designs. These blanks have a special coating. The coating is made from polymer or polyester. This layer helps the sublimation ink stick to the blank. You can find sublimation blanks in many shapes. Some examples are mugs, shirts, phone cases, and keychains.

Tip: Pick blanks with at least 65% polyester. This helps the ink stay on better. It also makes your colors look brighter.

You should use blanks that are white or light colored. Sublimation ink is see-through. It looks best on light backgrounds. Dark blanks hide your design. They also make colors look dull. Cotton and silk do not work unless they have a special coating. The ink will not stick, and your design may fade or peel.

Here are some common sublimation blanks and what they are used for:

Sublimation Blank Type | Material | Common Uses | Tips for Effectiveness |

|---|---|---|---|

Tazas | Ceramic with polymer coating | Personalized gifts, promotional items | Use smooth coatings for bright, long-lasting prints |

T-Shirts and Apparel | Polyester fabrics or polyester blends | Custom designs, uniforms | More polyester gives you brighter colors |

Fundas telefónicas | Hard plastic or rubber with sublimation coating | Custom phone accessories | Make sure the case fits and has a good coating |

Keychains | Metal or acrylic with sublimation coating | Small personalized items, giveaways | Use high-quality blanks for clear, detailed prints |

Coasters | Ceramic, cork, or MDF with coating | Home décor, promotional products | Even coatings help avoid print problems |

Aluminum Plates | Aluminum sheets with sublimation coating | Plaques, awards, decorative signs | Smooth coatings give you better prints |

Glassware | Glass with sublimation coating | Custom drinkware, gifts | Be careful not to scratch the coating before printing |

How They Work

Sublimation blanks let the dye ink become part of the surface. First, you print your design with sublimation ink on special paper. Next, you put the paper on the blank. Then you use heat and pressure. The heat turns the ink into a gas. The gas goes into the open pores of the coating. When the blank cools, the pores close and trap the ink.

This makes a print that will not peel or crack. The colors stay bright for a long time. Good blanks take in the ink well. They also handle heat and pressure without breaking. You get the best results with smooth, even coatings.

Blanks made from polyester or blends with lots of polyester give you the brightest colors.

Light-colored blanks show your design best because the ink is see-through.

Natural fabrics and dark blanks do not work well for sublimation.

Note: Always check if your blanks have the right coating. This helps your designs look sharp and colorful every time.

Using Sublimation Blanks

Sublimation Process

You can create custom items with the sublimation process. This method uses heat and pressure to transfer your design onto sublimation blanks. You start by printing your image with sublimation ink on special paper. The ink stays on the paper until you apply heat.

Here are the basic steps you follow for sublimation:

Print Your Design

Use a sublimation printer and sublimation ink to print your image on sublimation paper. Make sure your design fits the blank you want to use.Prepare the Sublimation Blank

Clean the surface of your blank. Dust or oil can stop the ink from bonding well.Align and Secure the Transfer

Place the printed paper face-down on the blank. Use heat-resistant tape to keep it in place.Heat Press the Blank

Set your heat press to the right temperature and time. Press the blank with firm, even pressure. The heat turns the sublimation ink into a gas. The gas moves into the coating of the blank.Remove and Cool

Take the blank out of the press. Let it cool before you touch the design. The ink becomes part of the blank, so your image will not peel or crack.

Tip: Always check the recommended time and temperature for each type of blank. Too much heat can damage the coating. Too little heat can cause faded colors.

To make sure your sublimation process works well, you can look at some important metrics:

Limit of Blank (LOB): This tells you the highest signal you can get from a blank with no ink.

Limit of Detection (LOD): This shows the lowest amount of ink you can see on your blank.

Limit of Quantification (LOQ): This is the smallest amount of ink you can measure with good accuracy.

Calibration curve linearity: You want your results to be accurate across different ink amounts.

Signal reproducibility: Try to keep your results steady by averaging several tests. Aim for less than 15% difference between them.

You can also improve your results by using even coatings and avoiding large crystals or uneven spots on your blanks.

Equipment Needed

You need the right tools to get the best results from sublimation. Each piece of equipment plays a key role in the process.

Here is what you need for successful sublimation:

Sublimation Printer: This printer uses special sublimation ink. It prints your design onto sublimation paper.

Tinta de sublimación: This ink turns into a gas when heated. It bonds with the coating on your blank.

Papel de sublimación: This paper holds the ink until you press it onto the blank.

Heat Press: This machine applies heat and pressure to transfer your design. You can choose from different types, like clamshell or swing-away presses.

En blanco de sublimación: These are the items you want to decorate. They must have a polyester or polymer coating.

When you pick your heat press, look at these important features:

Specification | Description |

|---|---|

Size (Platen Size) | Pick a size that matches your blanks. Small presses work for mugs or keychains. Large presses fit shirts or plates. |

Temperature Capabilities | You need precise control for different blanks and designs. |

Pressure Settings | Adjustable pressure helps you get even transfers. |

Heating Element Design | Clamshell presses save space. Swing-away presses give better access for thick blanks. |

Control Features | Digital displays and presets make it easier to set time and temperature. |

Build Quality & Durability | Strong frames and good materials last longer and give better results. |

Note: Use uniform methods, like a good heat press or a robotic sprayer, to keep your results steady. This helps you avoid problems like uneven colors or blurry designs.

With the right equipment and careful steps, you can make bright, lasting designs on many types of sublimation blanks.

Types of Sublimation Blanks

When you start with sublimation, you will see many types of blanks. Each blank works best for certain projects. You should always choose white or light-colored sublimation surfaces. This helps your colors look bright and clear.

Sublimation Fabric Blanks

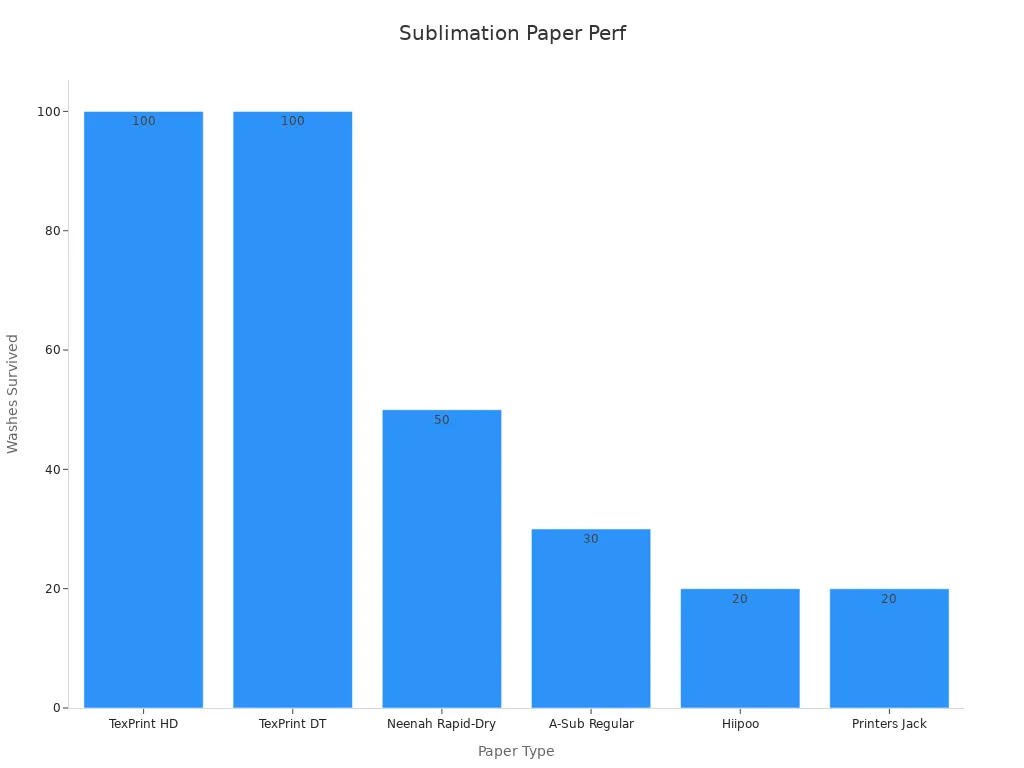

You can use sublimation fabric blanks to make custom shirts, bags, and home décor. These blanks use polyester or blends with high polyester content. Sublimation fabric holds the ink deep in the fibers. This makes your designs last longer and look more vibrant. For example, sublimation shirts keep their color after many washes. A-Sub Regular paper works well on polyester fabric and fades only 30% after 30 washes. You should avoid cotton unless it has a special coating. Sublimation fabric blanks give you the best results when you want soft, washable items.

Sublimation Mugs

Sublimation mugs are one of the most popular choices. You can use them for gifts, business promotions, or personal use. These mugs have a polymer coating that bonds with the ink. When you use TexPrint HD or TexPrint DT paper, your mugs can survive over 100 dishwasher cycles with only 5% fading. You will not see ink bleed, even on curved surfaces. Always pick mugs with a smooth, white coating. This helps your designs stay sharp and colorful.

Papel de sublimación | Best For | Durability / Washes or Cycles | Key Performance Metrics and Notes |

|---|---|---|---|

TexPrint HD | Mugs, ceramics | 100+ dishwasher cycles, 5% fade | Zero ink bleed; best for hard surfaces |

TexPrint DT | Mugs, ceramics | 100+ dishwasher cycles, 5% fade | Durable transfer; not for fabrics |

Tip: Always use heat-resistant tape to keep your design in place on mugs during pressing.

Sublimation Tumblers and Bottles

You can decorate sublimation tumblers and bottles for sports, travel, or gifts. These blanks have a special coating that lets the ink bond well. Tumblers and bottles come in many shapes and sizes. You should use a heat press or mug press that fits your blank. Tumblers need even pressure for the best results. Always check that your bottles have a white or light base. This helps your colors pop and keeps your design looking fresh after many uses.

Other Items

You can also use sublimation on many other items. Keychains, coasters, mouse pads, and phone cases all work if they have the right coating. You can even find aluminum plates and glassware made for sublimation. Always check that your blank is made for sublimation. This helps you avoid faded or peeling designs. You can try new projects and see which sublimation surfaces work best for you.

What to Avoid in Sublimation

Unsuitable Materials

You need to pick the right materials for sublimation. Some items do not work well and can ruin your project. Avoid using cotton or silk fabric. These materials do not hold the ink, so your design will fade or wash out quickly. Always check if your blank has a polyester or polymer coating. If you use plain ceramics or glass without a special coating, the ink will not bond. You should also skip dark-colored blanks. The colors from sublimation ink look best on white or light surfaces.

Here is a quick table to help you choose:

Material Type | Good for Sublimation? | Notes |

|---|---|---|

Polyester Fabric | Sí | Bright colors, long-lasting prints |

Cotton Fabric | No | Ink does not bond, fades fast |

Coated Mugs | Sí | Needs polymer coating |

Plain Mugs | No | Ink will not stick |

Coated Tumblers | Sí | Must have white or light base |

Plain Tumblers | No | No coating, poor results |

Coated Bottles | Sí | Check for special coating |

Tip: Always read the label before you buy blanks. Look for words like “sublimation-ready” or “polymer-coated.”

Common Mistakes

You can avoid many problems by watching out for common mistakes. One big mistake is using the wrong temperature or time on your heat press. If you use too much heat, you can burn the coating. Too little heat will cause faded designs. Make sure you use the right pressure for each blank. Uneven pressure can lead to blurry images, especially on mugs and tumblers.

Another mistake is not cleaning your blanks before pressing. Dust or oil can block the ink from bonding. Always wipe down your fabric, mugs, or bottles before you start. Do not forget to use heat-resistant tape to keep your transfer in place. If your paper moves, your design may look ghosted or blurry.

Remember: Practice makes perfect. Test your settings on a spare blank before you start your main project.

Sublimation Tips

Choosing Quality Blanks

You want your finished products to look bright and last a long time. Start by picking high-quality sublimation blanks. Look for blanks made from polyester or polyester blends with at least 65% polyester. These materials absorb sublimation ink well and handle heat without damage. Choose blanks that are white or light-colored. Designs show up best on these surfaces because the ink is transparent. Avoid natural fabrics like cotton or silk unless they have a special coating. These fabrics do not hold the ink, and your designs may fade quickly.

Premium blanks often cost more, but they give you sharper and more vibrant prints. Dark-colored blanks do not work well because your design will not show clearly. When you select sublimation paper, check that it uses a high-quality base made from virgin wood pulp. Good paper should feel dense and strong. It should also have a smooth surface and dry quickly after printing. A uniform coating on the paper helps the ink transfer evenly. Some papers have an anti-curl coating, which keeps them flat during heat pressing.

Tip: Always check the label for “sublimation-ready” or “polymer-coated” to make sure your blank will work.

Preparation and Handling

Proper preparation helps you avoid mistakes and get the best results. Clean your blanks before you start. Dust, oil, or fingerprints can block the ink from bonding. Use a lint roller for fabric or a soft cloth for mugs and bottles. Make sure your workspace stays clean and free from debris.

Handle sublimation paper with care. Store it flat and away from moisture. When you print your design, let the ink dry before you touch the paper. Align your design carefully on the blank. Use heat-resistant tape to keep the paper in place during pressing. This prevents ghosting or blurry images.

Check your heat press settings before each project. Use the right temperature and time for your blank. Too much heat can damage the coating. Too little heat can cause faded colors. Always let your finished item cool before handling it. This helps the design set and keeps the colors bright.

Step | What to Do | Why It Matters |

|---|---|---|

Clean the blank | Remove dust and oil | Ensures ink bonds properly |

Handle paper gently | Avoid bending or touching the print | Prevents smudges and warping |

Align carefully | Use tape to secure transfer | Keeps design sharp |

Set correct heat | Follow recommended settings | Avoids damage or fading |

Remember: Careful preparation and handling make a big difference in your final results.

Sublimation blanks give you a strong base for custom designs. You get the best results when you choose the right materials and coatings. Always look for blanks with at least 65% polyester. Light colors help your designs stay bright. Avoid cotton because the ink will wash out. Try different blanks like shirts, mugs, or totes. Learn from each project and improve your skills.

Use blanks with at least 65% polyester for lasting prints.

Pick light-colored surfaces for true colors.

Avoid cotton and dark blanks.

Explore trusted brands like Cricut Infusible Ink Blanks or Artesprix.

Keep testing new ideas. Each project helps you get better at sublimation!

FAQ

What is the best temperature for sublimation?

You should use 375°F to 400°F for most blanks. Always check the instructions for your specific blank. Too much heat can damage the coating. Too little heat can cause faded colors.

Can you sublimate on cotton?

You cannot sublimate directly on cotton. Sublimation ink needs polyester to bond. If you want to use cotton, look for blanks with a special sublimation coating.

Why do my sublimation prints look dull?

Your prints may look dull if you use the wrong paper, low-quality blanks, or incorrect heat settings. Make sure you use high-polyester blanks and follow the recommended time and temperature.

Do you need to mirror your design before printing?

Yes, you need to mirror your design before printing. The image will transfer in reverse when you press it onto the blank. Most design software has a mirror or flip option.

How do you prevent ghosting in sublimation?

Always secure your transfer paper with heat-resistant tape. Do not move the paper after pressing. Let the blank cool before removing the paper. This helps you avoid blurry or double images.