Imagine you made a t-shirt and are holding it. It could become someone’s favorite shirt. You want a business that matches your creativity. You also want it to fit your schedule and your budget. Many business owners pick heat transfer printing for this reason. It lets you try new markets and start with little money. You can sell to people on Etsy or Amazon. You can make things for clothes, gifts, or company logos. You can show your own style in your products. Customer Success Stories prove passion and flexibility help ideas become best-sellers.

Control de llave

Heat transfer printing is simple and cheap. You can use it to start a custom product business at home. – There are different printing methods like sublimation and DTF. Each one works best on certain fabrics and designs. – You can make popular things like clothes, gifts, and promo items. The prints are bright and last a long time. – Good tools and clear designs make your products special. This helps customers want to buy from you again. – Show your work on social media. Learn from your mistakes. This will help your business get bigger and stronger.

Why Heat Transfer Printing

What It Is

Heat transfer printing lets you make custom products easily. You can pick from different ways to print. Each way has its own good points. The most common types are sublimation, DTF (Direct-to-Film), and screen printed transfers. Here is a simple table to show how they are different:

Aspecto | Impresión por sublimación | Direct-to-Film (DTF) Printing |

|---|---|---|

Process Steps | Designing, printing, transferring | Refining, printing, curing, heat pressing, removing film |

Print Feel | Ink infused into fabric; soft, no additional layers | Ink layered on fabric; noticeable layered feel |

Fabric Compatibility | White/light polyester fabrics | Cotton, polyester, fleece, nylon, blends |

Vitalidad de color | High, may fade over time | Vibrant and durable |

Print Durability | Ink becomes part of fabric; won’t peel | Durable, lasts many washes |

Design Complexity | Great for large, photo-realistic images | Excels in detailed, small to medium designs |

Product Range | Apparel, mugs, plates, more | Mainly apparel |

Screen printed transfers use ink on special paper. A heat press puts the design on the item. This way works on many kinds of fabric, like cotton and blends. You get bright colors and prints that last a long time.

Key Benefits

Starting a business with heat transfer printing is easy and cheap. The machines are small, so you can use them at home. You do not need to study for years. You just need to learn about heat and time. The process is quick, even for small or colorful orders. You can make prints that look sharp and clear. You also save money. Each shirt usually costs only $1 to $2 to make. You can make 10 to 30 things every hour. This helps you finish orders fast.

Consejo: Heat transfer printing lets you try new ideas without spending a lot. You can test what designs your customers like best.

Why It’s Popular

More people use heat transfer printing every year. Online shops and print-on-demand make it simple to sell things. You can offer custom shirts, mugs, or bags with little risk. DTF printing is fast and works on many fabrics. You can fill small orders quickly. Customers like the bright colors and personal designs. Eco-friendly inks and less waste are good for the planet too.

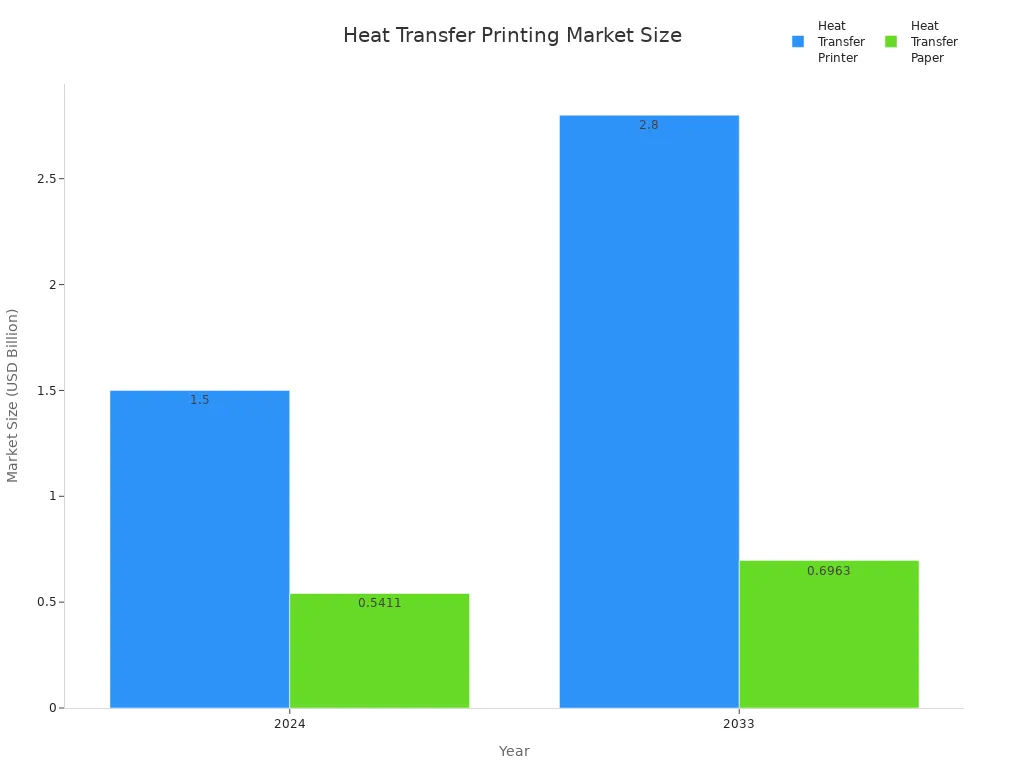

The heat transfer printing market keeps getting bigger. Experts think it will almost double by 2033. This means you have more chances to turn your ideas into a great business.

Customer Success Stories

You can get ideas from real people’s stories. They used heat transfer printing to make best-selling products. These Customer Success Stories show you can grow your business. You can reach new customers and build something that lasts. Let’s see how people like you found success with apparel, gifts, and promotional items.

Apparel

You can start with a t-shirt and build a strong business. Many people use sublimation heat transfer printing for custom clothes. They pick blanks with lots of polyester for bright prints. You can make shirts, sweatshirts, and sportswear with cool logos or pictures.

Start an online store and sell on Etsy or Amazon.

Show your designs on social media to get fans.

Sell many items to teams, clubs, or local shops.

Listen to what customers say and make your products better.

Trevor Murphy from Anhyzer Designs loved disc golf. He turned that into a top-selling apparel brand. He used good blanks and shared his story online. He built a loyal group of customers. You can do this too by picking the right tools and learning from others who use sublimation printing. Your prints will stay bright and soft after many washes.

Consejo: Try more than just t-shirts. Make hoodies, hats, or sports clothes. Selling different things helps you find more customers and keeps your business strong.

Regalos

You can make special gifts that people love to give. Heat transfer printing lets you add names or pictures to almost anything. Many Customer Success Stories started with simple ideas that became best-sellers.

Description & Material | Profit/Market Insight | |

|---|---|---|

Earbud/Mask Cases | Hard shell, polyester coating, heat printed | Cheap, easy to make, popular on Amazon |

Denim Placemats | 100% cotton denim, custom transfers | More products, great for custom designs |

Tool Belts | Cotton/poly blends, 2-color transfers | Special gifts for people who like DIY |

Kitchen Towels | Cotton, bulk buy, 2-color transfers | Sold on Etsy, $8 profit per towel |

Kitchen Accessories | Pot holders, oven mitts, instant pot covers | Sold as sets, home cooks like them |

You can follow trends and special days. For example, Valentine’s Day mugs and shirts always sell well. Use heat transfer vinyl or sublimation for colorful, dishwasher-safe designs. Add fun sayings or characters to make your gifts stand out. Personalized wine tumblers and makeup bags also sell well, especially if you use pop culture ideas.

You can sell more by offering bundles or sets. People like matching kitchen towels and accessories, especially when they see your designs on social media.

Promotional Items

You can help other businesses by making custom products. Many Customer Success Stories come from companies using heat transfer printing for branded items. These include tote bags, mugs, and phone cases. One apparel company used ninja transfer’s technology. They cut costs by 40% and filled orders 50% faster. Their prints looked better and lasted longer. This made customers happy and brought them back.

You can use advanced heat transfer printing for licensed designs, like Disney DTF prints. You can also use eco-friendly packaging with UV DTF custom prints. These choices help you stand out and meet what brands want.

Make more products to reach new customers.

Show your work on social media to get business clients.

Pick good equipment for quality and fast work.

When you make more than t-shirts and offer many promotional items, you find new ways to earn money and keep your business safe from changes.

Customer Success Stories show you can grow by being creative, using smart marketing, and having the right tools. You can build a business that lasts and inspires others to do the same.

Steps to Success

Materials & Equipment

Pick the right tools to do well. A good heat press gives even heat and pressure. This makes your prints look great every time. You need a special sublimation printer with the right ink. Regular printers will not work for this. Use a computer with design software to make your art.

Here is a simple checklist to help you start:

Heat press (swing-away types are easy for beginners)

Sublimation printer with sublimation ink

Design software on your computer

Sublimation paper and heat-resistant tape

Protective paper for your press

Weeder and vinyl remover for small details

Teflon sheet to keep your press clean

Pre-printed DTF transfers to make more products

Consejo: Good equipment is worth the money. Your customers will see the better quality and want to buy again.

Design & Production

Your designs help your products stand out. Use design software to make bold and clear images. A heat press with digital controls gives you great results. Sticky carriers for vinyl save time when you weed. For big orders, use an assembly line. This helps you work fast and do a good job.

Keep your workspace neat so you can find things fast. Use laser tools to place designs just right. Non-stick covers on your press help it work smoothly. These steps help you work faster and keep your quality high.

When you get good at your process, you can take more orders and grow your business with confidence.

Marketing

You can find more customers by sharing your work online. Social media like TikTok, Instagram, Facebook, and Pinterest help you show your products. Post videos of your printing or finished items. People like to see how things are made.

Paid ads, emails, and special deals help you sell more. Keep your followers interested with new designs and behind-the-scenes posts. Fun and steady marketing helps your brand and brings loyal fans.

Your story and products can inspire others. Share them with pride and watch your business grow.

Tips and Mistakes

Actionable Tips

You can build a strong business by working smarter and focusing on quality. Many successful entrepreneurs share these tips to help you grow:

Invest in professional-grade heat transfers. High-quality materials make your products stand out and keep customers coming back.

Use online design tools like Easy View to create artwork quickly. This saves time and helps you launch new designs faster.

Find your niche. Target a specific group or market with unique designs and print locations.

Offer samples to show your quality. Samples build trust and help you win new customers.

Post on social media often. Share your process and finished products to attract more buyers.

Upsell to your current customers. Suggest matching items or bundles to increase your sales.

Master the basics: time, temperature, and pressure. These three things make every print look its best.

Use the right accessories, like heat pillows or pressure guides, to improve your results and work faster.

Consejo: Focus on quality every step of the way. Your reputation will grow, and so will your business.

Common Mistakes

Many beginners make the same mistakes. You can avoid them and save time by learning what to watch out for:

Common Mistake | How to Avoid |

|---|---|

Wrong time, temperature, or pressure | Always follow the instructions for each transfer type. |

Poor design placement | Try different spots, like the left chest or shoulder, not just the center. |

Test your transfers on each fabric before making a big batch. | |

Uneven pressure | Keep your press flat and use tools for even pressure. |

Color mismatches | Check colors with swatches before printing. |

Skipping cost analysis | Add up all costs and set prices that cover your work and materials. |

Bad storage of transfers | Store transfers flat in a cool, dry place to prevent damage. |

Skipping pre-press steps | Always pre-press garments to remove moisture and wrinkles. |

Low-quality design files | Use high-resolution images in the right format for sharp, clear prints. |

Getting Started

You can start your own heat transfer printing business with just a few steps:

Pick a niche you know well, like a hobby group or local team.

Choose heat transfer printing. It is easy to learn and does not need much equipment.

Create your designs using simple tools like Canva or Easy View. You do not need to be a pro designer.

Buy a reliable heat press. Even affordable models can give you great results.

Connect with support networks. Companies like Stitch It International offer guides, financing, and community help.

Stay active on social media and join online groups. You will find tips, inspiration, and new friends.

You have everything you need to get started. Take the first step, and you can turn your ideas into best-selling products!

You have read how Customer Success Stories show the importance of knowing your materials, trying out your settings, and picking the right tools. If you work hard on quality and keep getting better, you will see more happy customers, more orders, and better products. Use these steps that work and try them with your own ideas. Begin your heat transfer printing journey now. With good planning and help, you can make a business that inspires others.

Preguntas frecuentes

How much money do I need to start heat transfer printing?

You can start with less than $500. Buy a basic heat press, a printer, and some blank shirts. Start small and grow as you learn. Many successful businesses began with just a few tools and a big dream.

Consejo: Start with what you have. Upgrade as your sales grow!

What products can I make with heat transfer printing?

You can create many items, such as:

T-shirts and hoodies

Tote bags

Mugs and tumblers

Hats and caps

Kitchen towels

Your creativity sets the limit. Try new ideas and see what your customers love!

How do I make my designs stand out?

Use bold colors and clear images. Listen to your customers and follow trends. Share your story and show your process online. People love unique designs and personal touches.

🌟 Your passion shines through your work. Let it inspire others!

Can I run this business from home?

Yes, you can! Many people start in a spare room or garage. The equipment fits in small spaces. You control your schedule and work at your own pace. Home-based businesses can grow into something amazing.

What if I make a mistake on a product?

Mistakes happen to everyone. Learn from them and keep going. Practice makes you better. Offer the product as a sample or gift. Each error teaches you something new and brings you closer to success.

Remember, every great business started with a first try!