You should pick the Right Film for your products. Think about your materials and what your customers like. DTF printing is good for custom clothes. It is also fast and costs less money. Many small businesses use DTF now. It gives quick results and lets you make many designs. If you want to print on polyester items, 3D sublimation may be better. It is also good for pictures that look real. The dye sublimation market is very big. It is worth $16 billion. More people want custom things, so it keeps growing. Your business goals help you choose the best film. Your target market matters too.

Control de llave

DTF printing can be used on many materials. It is good for custom clothes and items for promotion.

3D sublimation gives very clear and real-looking prints. It works best on polyester and coated things.

Think about your business goals and who will buy your products. This helps you pick DTF or sublimation for your products.

DTF is fast for making small groups of items. Sublimation works well for big orders of polyester things.

Both ways of printing last a long time. DTF prints can feel a little rough. Sublimation prints feel smooth and part of the item.

Overview

DTF Printing

DTF printing works for many products. You can use it on cotton, polyester, and some other things. DTF means Direct-to-Film. First, you print your design on a special film. Then, you use heat to move the design onto your product. There are five steps: refine, print, cure, press, and peel. The finished product feels a little bumpy.

Consejo: DTF printing is good if you want to make custom clothes, promo items, or decorations. You can make cool sportswear, team shirts, and branded things for your business.

Here is a simple table to compare DTF and sublimation printing:

Aspecto | DTF Printing | Impresión por sublimación |

|---|---|---|

Material Compatibility | Works on many things like cotton and polyester | Best for light polyester or coated items |

Calidad de impresión | Bright colors, 3D look, lasts long | Looks like a photo, smooth surface |

Equipment | DTF printer, heat press, film sheets | Sublimation printer, inks, heat press |

Cost Considerations | Good price for small or medium jobs | Best for making lots of things |

Speed and Efficiency | Fast, great for quick orders | Good for making many at once |

Custom clothes

Promo items

Sportswear and team shirts

Decorations for inside

3D Sublimation

3D sublimation printing uses heat to put dye into your product. The finish is smooth and not bumpy. This works best on light polyester or coated things. There are three steps: design, print, and transfer. You can make pictures that look very real and clear.

Many businesses use 3D sublimation. You can make clothes, custom shirts, and soft signs. You can also make promo items like mouse pads, phone cases, key chains, and pet bowls.

Clothes

Custom shirts

Soft signs

Mouse pads

Phone cases

Key chains

Pet bowls

If you want to pick the Right Film for your business, think about what materials you use and what you want to sell. DTF lets you use more types of fabric. 3D sublimation works best on polyester and coated things.

Materials

DTF: Fabric Types

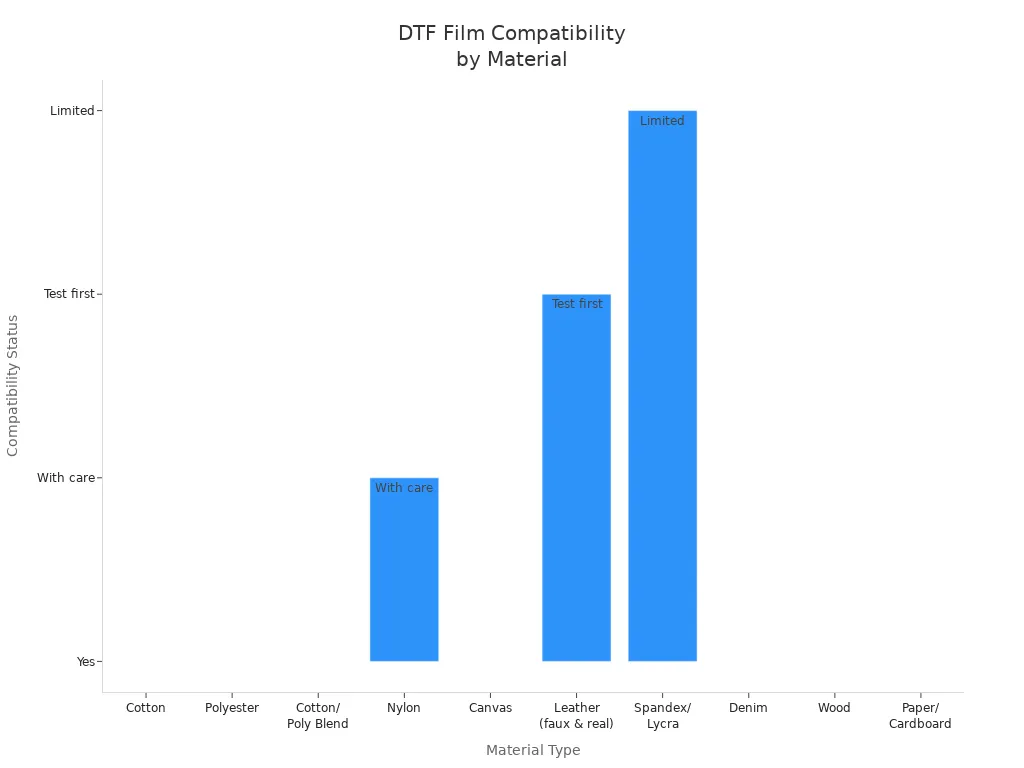

DTF film works on many materials. This makes DTF a good choice for many businesses. You can use DTF on cotton, polyester, blends, denim, canvas, and wood. It also works on both light and dark fabrics. This lets you make lots of different products for your customers.

Here is a table that shows how DTF film works with different materials:

Material | Is It DTF-Compatible? | Recommended Use | Notes |

|---|---|---|---|

Algodón | ✅ Yes | T-shirts, tote bags, sweatshirts | Sticks very well |

Poliéster | ✅ Yes | Sportswear, jerseys | Does not bleed like sublimation |

Cotton/Poly Blend | ✅ Yes | Hoodies, lightweight tees | Colors stay bright |

Nylon | ⚠️ With care | Jackets, windbreakers | Use less heat and pressure |

Canvas | ✅ Yes | Totes, aprons, banners | Prints clearly on texture |

Leather (faux & real) | ⚠️ Test first | Patches, accessories | Needs careful heat |

Spandex / Lycra | ⚠️ Limited | Leggings, athletic gear | May crack if stretched |

Denim | ✅ Yes | Jackets, jeans | Good for bold prints |

Madera | ✅ Yes | Signs, ornaments | Best on flat surfaces |

Paper/Cardboard | ✅ Yes | Packaging, gift boxes | Great for custom branding |

Cotton and polyester give the best results. These fabrics soak up ink and keep colors bright. Blends also work well and last a long time. Some materials, like nylon or spandex, need special care. You might need to change the heat or pressure to avoid damage. Always test first if you want to print on leather or wood. Because DTF works on so many things, you can make clothes and custom packages.

Sublimation: Polyester Focus

Sublimation printing works best on polyester. The fabric should have at least 65% polyester for bright prints. If you use 100% cotton, the ink will not stick. Blends with less polyester will only keep some of the design.

Sublimation printing sticks best to polyester.

100% cotton does not work for sublimation.

Blends keep only some ink, based on polyester amount.

You can also use sublimation on coated things, like mugs or phone cases. This process gives smooth and real-looking pictures. If your business makes sportswear, banners, or gifts, polyester is the best. You get sharp images and colors that last after many washes. Polyester’s smooth surface helps the ink stay, so your products look bright and professional.

Calidad de impresión

DTF: Colors and Texture

You get bright and bold colors with DTF printing. The process uses digital color profiles, so you can match brand colors with high accuracy. DTF printers use CMYK plus white ink, which means you can print unlimited colors. You do not need to worry about color limits like in screen printing. You can also print smooth gradients and detailed images.

Here is a table that shows how DTF compares to traditional screen printing:

Feature | Screen Printing | DTF |

|---|---|---|

Max Colors | ~8 (complex setup) | |

Gradients | Limited | Excellent |

Photo Quality | Difficult | High-res compatible |

Setup Time | Long (per color) | None |

Color on Black Garments | Requires white underbase | Standard with white layer |

Brand Color Accuracy | Manual mixing | Digital color profiles |

You will notice that DTF prints feel a bit raised or bumpy. This texture comes from the film and powder adhesive. Some people like this 3D effect, especially for bold logos or designs. DTF works well on both light and dark fabrics. You can print on black shirts without extra steps. If you want to create colorful, eye-catching designs, DTF gives you a lot of freedom.

Consejo: DTF is a great choice if you want to print many colors, smooth fades, or detailed artwork on different fabrics.

Sublimation: Photorealistic Results

Sublimation printing gives you smooth and soft prints. The ink becomes part of the fabric, so you do not feel any extra layer. You get sharp, photorealistic images with this method. Sublimation works best for designs with lots of detail, like photos or complex graphics.

You can print bright colors, but only on light polyester or coated items. The colors stay true and do not fade easily. You will see that the print looks like it is part of the product. There are no bumps or rough spots. This makes sublimation perfect for sportswear, banners, and custom gifts where image quality matters most.

You get smooth, soft prints.

Colors look bright and last a long time.

Best for detailed or photo-like designs.

If your customers want products with a soft feel and high-quality images, sublimation printing will meet their needs.

Durabilidad

DTF: Wear Resistance

You want your products to last. DTF printing gives you strong prints that can handle daily use. The ink sits on top of the fabric, and the adhesive powder helps it stick well. You can wash DTF-printed shirts many times without seeing much change. The colors stay bright, and the design does not peel off easily.

Here are some reasons why DTF prints last:

The adhesive powder creates a strong bond.

The print resists cracking and peeling.

You can wash DTF prints in a machine.

The design stays clear after many wears.

Consejo: Turn your DTF-printed clothes inside out before washing. This helps the design last even longer.

You may notice a slight texture on the print. This texture does not affect how long the design lasts. DTF works well for work uniforms, sportswear, and kids’ clothes. These items need to handle lots of movement and washing.

Durability Factor | DTF Printing Result |

|---|---|

Wash Resistance | Alto |

Peel/Crack Resistance | Alto |

Fade Resistance | Good |

Texture | Slightly raised |

Sublimation: Fade Resistance

Sublimation printing gives you prints that do not fade easily. The ink turns into gas and becomes part of the fabric. You do not feel any extra layer on the surface. This process makes the design last as long as the fabric itself.

You can wash sublimated items many times. The colors stay bright and sharp. You do not see cracks or peels because the ink is inside the fibers.

The print will not fade quickly.

The design will not crack or peel.

The fabric stays soft and smooth.

Nota: Sublimation works best on polyester. If you use other fabrics, the print may not last as long.

Sublimation is a great choice for sports jerseys, banners, and custom gifts. These products need to look good after many washes and lots of use.

Durability Factor | Sublimation Result |

|---|---|

Wash Resistance | Excellent |

Peel/Crack Resistance | Excellent |

Fade Resistance | Excellent |

Texture | Smooth, no extra layer |

You can trust both DTF and sublimation for durable prints. Your choice depends on your product and the material you use.

Cost

DTF: Investment

You should think about your budget before you start DTF printing. The price changes based on the setup you pick. Look at this table to see how much different DTF setups cost:

Setup Type | Cost Range | Components |

|---|---|---|

Entry-Level | $5,000 – $10,000 | Basic DTF printer, heat press, starter supplies, computer, and design software |

Mid-Range | $10,000 – $20,000 | Bigger printer, better heat press, curing oven, more supplies, and software |

Professional | $20,000+ | Large printer, many heat presses, powder system, curing tunnel, full inventory |

Entry-level setups cost less money. They are not good for big orders. If you want your business to grow, you may need a mid-range or professional setup.

Here is a list of common DTF costs:

DTF Printer: $2,000 to $15,000

Heat Press Machine: $300 to $1,500

Powder Shaker & Curing Oven (optional): $1,000 to $3,000

Software: $200 to $500

Maintenance: $50 to $200 each month

Electricity and Overheads: $50 to $150 each month

Consejo: Starting a DTF business can cost from $5,700 to over $40,000. Pick what fits your business size and goals.

Sublimation: Expenses

Sublimation printing costs are different. You need a sublimation printer, heat press, special inks, and paper. You should think about the costs you pay all the time. Here is a table that shows ongoing costs for both ways:

Printing Method | Ongoing Expenses |

|---|---|

DTF Printing | Adhesive powder, transfer films, pigment inks |

Impresión por sublimación | Sublimation ink, sublimation paper |

You will buy ink and paper for sublimation. These costs go up if you print a lot. DTF uses powder and film, which also cost money over time. Both ways need regular care and electricity.

Nota: Think about both starting costs and ongoing costs. This helps you pick the best way for your budget and business plan.

Applications

DTF: Product Range

You can use DTF printing to create many different products. This method works on cotton, polyester, blends, and even some non-fabric items. You get a lot of creative freedom because you do not need to stick to just one type of material. Here are some products you can make with DTF:

Personalized apparel (t-shirts, hoodies, hats)

Home décor (pillows, wall art, canvas prints)

Promotional products (tote bags, banners, aprons)

DTF printing lets you produce small batches or even single items. You do not need to worry about high setup costs. This makes it easy for you to offer custom designs and meet special requests. You can quickly change your product line to match what your customers want. If you want to grow your business, DTF gives you the flexibility to try new ideas without a big investment.

Consejo: DTF works well for on-demand printing. You can make products as soon as someone orders them.

You can see how DTF compares to 3D sublimation in this table:

Process | Material Compatibility | Creative Freedom |

|---|---|---|

DTF | Works on cotton, polyester, blends, and more | Alto |

3D Sublimation | Requires polyester-rich surfaces | Limited |

Sublimation: Best Uses

Sublimation printing shines when you want smooth, bright, and detailed images. You need polyester-rich materials or special coatings for the best results. This method is perfect for many popular promotional and custom products. Here are some top-selling items you can make with 3D sublimation:

Shirts

Tote Bags

Magnets

Tazas

Bookmarks

Alfombrillas de ratón

Towels

Stickers

Coasters

You can also create keychains, photo blanks, puzzles, glass cups, and more. Sublimation works best if you want to print full-color photos or detailed graphics. You get a soft feel and long-lasting color.

Material compatibility shapes what you can offer. DTF lets you print on many fabrics, so you can expand your product range easily. Sublimation limits you to polyester or coated items, but you get top-notch image quality. Think about your business goals and the types of products your customers want. This will help you choose the right method for your needs.

Choosing the Right Film

Business Types

You need to match your printing method to your business type. Small businesses, startups, and large companies all have different needs. If you run a small shop or a startup, you may want to offer many custom products. DTF printing gives you this flexibility. You can print on cotton, polyester, blends, and even leather. This means you can make t-shirts, tote bags, hats, and more without buying extra machines. DTF works well for print-on-demand businesses. You can handle small or medium orders without wasting money.

If you own a larger business or want to focus on high-volume orders, 3D sublimation might fit better. Sublimation works best for big batches of polyester items. You can print many shirts, mugs, or banners quickly. The process is simple and fast, so you can meet tight deadlines. Some creative businesses use 3D sublimation to make unique products, like custom phone cases or photo gifts. You need to invest in the right equipment and plan for regular maintenance.

Here is a table to help you see which method fits your business:

Tipo de negocio | DTF Printing | 3D Sublimation Printing |

|---|---|---|

Small Business | Great for custom, small-batch, and diverse items | Good for custom gifts on polyester or coated items |

Startup | Flexible, easy to scale, low minimums | Best for niche markets with polyester products |

Large Operation | Handles many SKUs, needs more equipment | Efficient for large runs of polyester goods |

Consejo: If you want to grow your product range or try new ideas, DTF gives you more options. If you want to focus on photorealistic prints and fast production, sublimation is a strong choice.

Product Needs

You should think about what products you want to sell before picking the Right Film. DTF printing lets you work with many materials. You can print on light or dark fabrics, cotton, blends, and even some hard surfaces. This makes DTF a smart choice if you want to offer a wide range of custom goods. You can make shirts, hats, bags, and even wood signs.

Sublimation printing works best for polyester and coated items. You get smooth, bright, and detailed images. If your customers want soft-feel shirts, sportswear, or photo gifts, sublimation is the Right Film for you. You can print full-color photos on mugs, mouse pads, and towels. The prints last a long time and do not crack or peel.

Order size and turnaround time also matter. DTF printing works for any order size, but the process takes a bit longer because of extra steps. Sublimation is faster for big orders, so you can finish large batches quickly.

Here is a table to compare product needs:

Feature | DTF Printing | Impresión por sublimación |

|---|---|---|

Personalización | Works on many materials | Best for polyester and coated |

Order Size | Good for small or large runs | Best for large batches |

Turnaround Time | Takes more steps | Faster for big orders |

Calidad de impresión | Bright, raised, vivid | Smooth, photorealistic |

When you choose the Right Film, think about your long-term goals. If you want to expand your product line or try new fabrics, DTF gives you more freedom. If you want to focus on high-quality images on polyester, sublimation is the best fit.

Note: DTF is versatile and works on many fabrics and colors. Sublimation gives you the best photo prints on polyester.

Pros and Cons

DTF: Advantages

DTF printing gives your business many good things. You can use it on lots of materials. The prints look bright and clear. It is easy to learn how to use DTF. You can start printing fast. The prints last a long time. They do not wash out or wear off quickly. DTF saves you money compared to other ways to print.

Advantage | Descripción |

|---|---|

High-quality Prints | You get bright images with sharp details. |

Versatilidad | You can print on cotton, polyester, and blends. |

Durabilidad | Your prints stay strong after many washes. |

Cost-effectiveness | You spend less on supplies and setup. |

User-Friendly | You learn DTF fast and start printing soon. |

Consejo: DTF printing lets you make many products. You do not need extra machines.

DTF: Disadvantages

DTF printing has some problems you should know about. Ink can smudge if you do not handle the film right. Pictures may blur if you are not careful. Colors can look different sometimes. The film might wrinkle during printing. Sometimes, the print does not stick well. White ink can cause trouble. Printer heads may clog. Printhead strikes can happen. The film may not move to the product right.

Ink can smudge

Pictures may blur

Colors can change

Film might wrinkle

Prints may not stick

White ink can be tricky

Printer heads may clog

Printhead strikes happen

Film may not transfer well

These issues can make prints look worse and not last long. You need to check your printer often and handle things with care.

Sublimation: Advantages

3D sublimation printing gives you sharp, photo-like pictures. The ink goes into the material. Prints do not fade, crack, or peel. You can use sublimation on polyester, ceramics, and metals. It works well for small orders and custom designs. You can print fast and make special items easily. Sublimation uses dry inks. This is better for the environment.

Advantage | Descripción |

|---|---|

High-Quality, Vibrant Prints | You get bright colors and smooth fades in every design. |

Durability & Longevity | Prints last long and do not fade or break. |

Versatility in Materials | You can print on polyester, ceramics, and metals. |

Cost-Effective for Small Runs | You do not pay high setup costs for small orders. |

Efficiency & Speed | You finish orders fast, even when time is short. |

Easy Customization | You can make gifts and branded items easily. |

Eco-Friendly Printing | You use dry inks that save water and avoid harsh chemicals. |

Sublimation: Disadvantages

3D sublimation printing has some limits. You can only use certain materials like polyester or coated items. The cost stays high for big orders. You cannot lower the price per item as much as with other ways. Sometimes, finished products are not as strong as those made with other methods.

Aspecto | 3D Sublimation Printing | Traditional Manufacturing |

|---|---|---|

Selección de material | Only works on some materials | Works on many materials |

Performance Stability | Properties may change | Properties stay the same |

Cost | High for special materials | Lower cost for big batches |

Not good for making lots of items

Price per item stays high, even for big orders

Only works on some materials

Nota: Think about what you want to make and how many you need before you pick sublimation for your business.

You need to think about your business goals when picking the Right Film. DTF printing lets you use many materials and gives you more choices. Sublimation makes polyester items look smooth and bright. Look at what products you want to sell, how much money you have, and what your customers want. Many experts say you should make a money plan and see what other businesses do. You should also think about what makes your business special. If you are not sure, you can ask people who know a lot about the industry for help.

Preguntas frecuentes

What is the main difference between DTF and 3D sublimation?

DTF works on many fabrics, including cotton and blends. 3D sublimation needs polyester or coated items. You get a raised print with DTF. Sublimation gives you a smooth, photo-like finish.

Can I use DTF or sublimation for dark fabrics?

You can use DTF on dark fabrics. The white ink layer helps colors stand out. Sublimation does not work well on dark fabrics. The ink blends into the fabric and colors look faded.

Which method lasts longer after washing?

DTF and sublimation both last a long time. Sublimation prints become part of the fabric, so they do not crack or peel. DTF prints stay bright and resist peeling, but you may feel a slight texture.

Is DTF or sublimation better for small orders?

You can use DTF for small or single orders. It does not need high setup costs. Sublimation also works for small runs, but you must use polyester or coated items.

What products can I make with each method?

DTF: T-shirts, hoodies, tote bags, hats, wood signs

Sublimation: Mugs, mouse pads, polyester shirts, coasters, phone cases

Choose based on your product ideas and the materials you want to use.