About Us

Tunosub

Sublimation Phone Case Manufacturing

Factory Profile

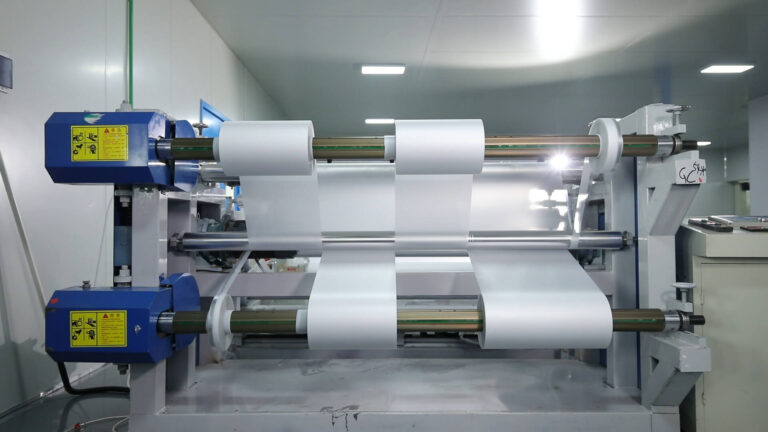

Fully automatic coating machine

Textile Factories

Flat Automatic Spraying Workshop

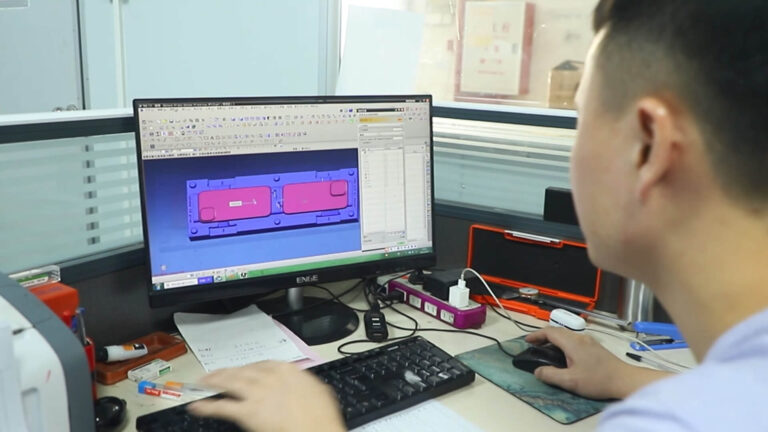

CNC, Mold & Stamping Department

Factory Profile

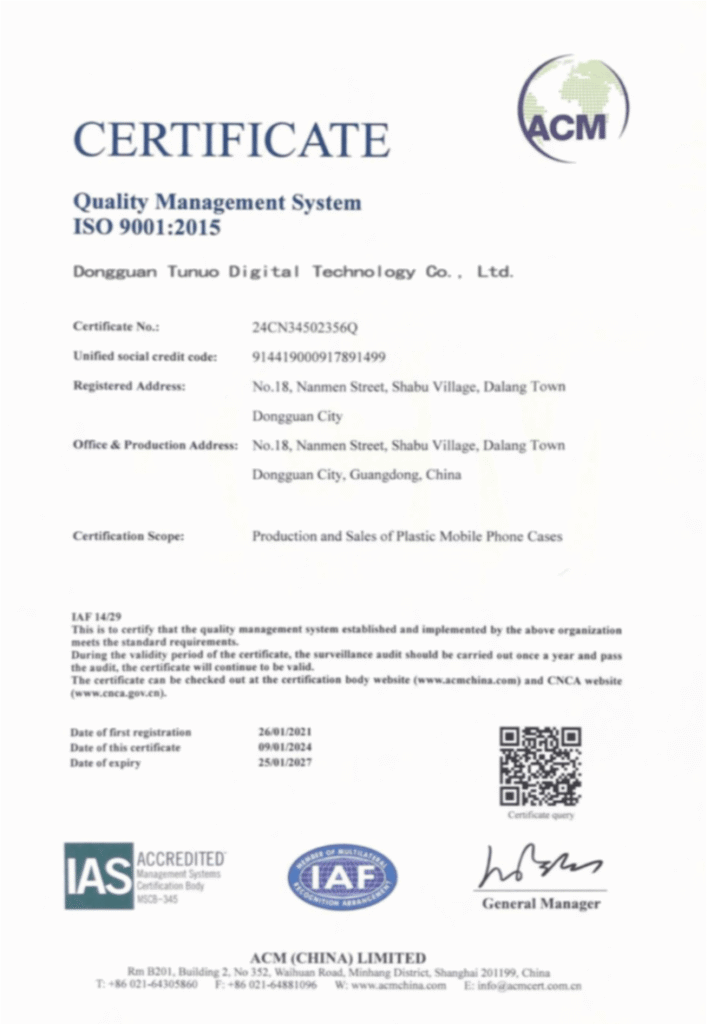

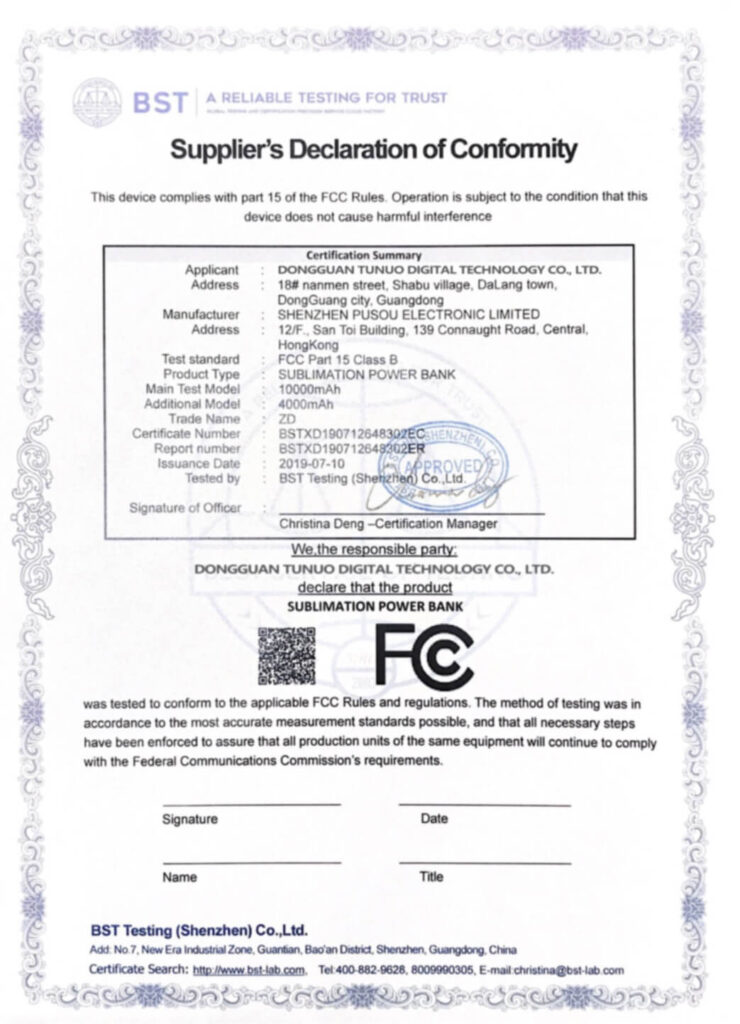

Qualifications & Certifications

Quality Control

1.Material Picking: Confirm materials received according to order.

2.Mould Installation Inspection: Oil temperature and machine confirmation ,mold cleaning.

3.First Injection: Ensure meets the sample or drawing and passed the test.

4.Injection Molding: Check the product parameter stability, no defects, no deformation

5.Process Inspection: Confirm product meets the requirements and test standards.

6.Inkjet/Silk Screen Printing: Checking ink color, light leakage, scratches and other appearance defects.

7.Baking: Check the baking temperature and baking time

8.Injection Molding: Ensure no appearance defects such as burrs, discoloration, scratches, dirt, etc.

9.Packaging: Check quantity, labeling and packaging methods same as order.

10.FQC Inspection: Random inspection of product appearance, quantity, labeling and mixing.

11.Finished Product Inspection: Check quantity and mark to prevent quantity errors and over-high stacking.

12.Shipping inspection: Full inspection of product quantity, model and outer box marking.

Production Process